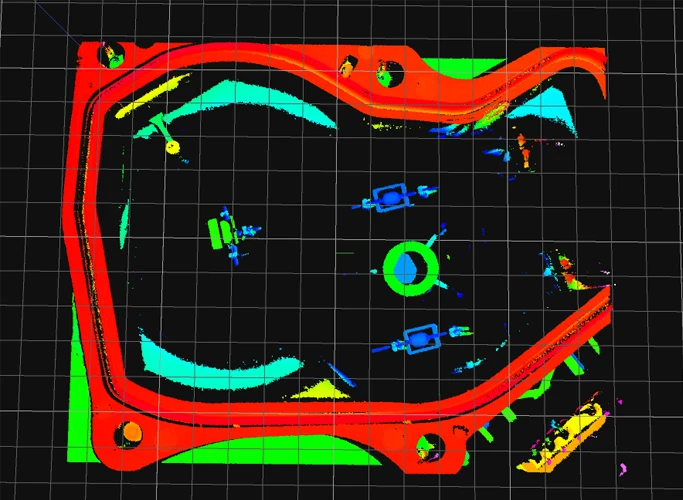

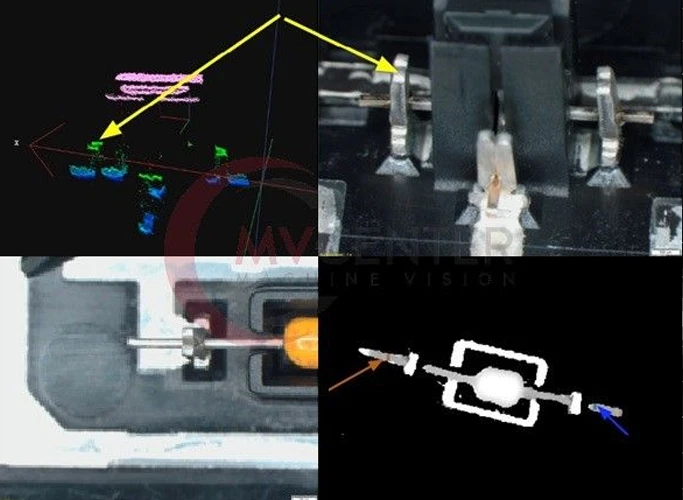

Inspection of 3D automotive parts is another inspection of the many fine and shiny parts inside the cover casing of a control component used in the automotive industry. The inspection takes place using 3D technology.

The inspection included such items as:

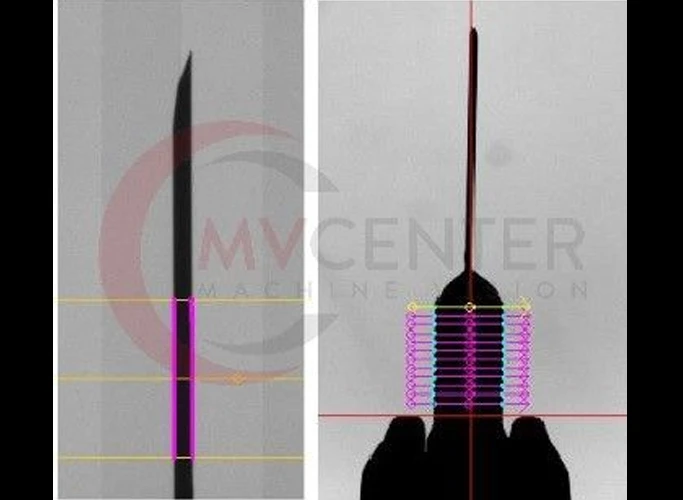

- Checking the presence of the sensor, the presence of the three steel wires (sensor legs) and the correctness of the clamping of these legs in the process of welding the components,

- Checking the presence (or absence, depending on the reference) of capacitors placed in plastic sockets, the presence and position of steel capacitor wires and the correctness of their clamping during welding,

- Checking the presence and correct position of the pins supplying the system,

- Checking the presence and correct positioning of the gasket placed around the lid.

A 3D scanner using a laser line was used to retrieve the point cloud. In the described application, the decision was made for an LMI-branded scanner – the Gocator 2330 whose resolution and field of view best matched the set inspection parameters. Repeatability of measurement in the X and Y axes was obtained at 0.075 mm, while in the Z axis at 0.02 mm.

Scanned product.

Examples of detection of OK and NOK elements – pins.

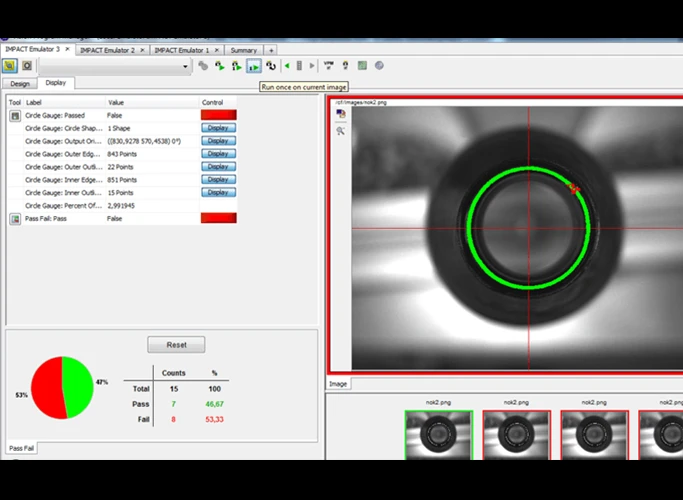

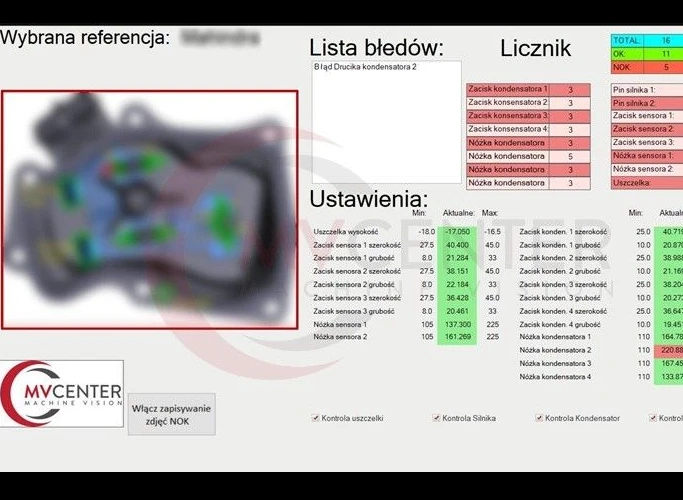

Video system user interface.

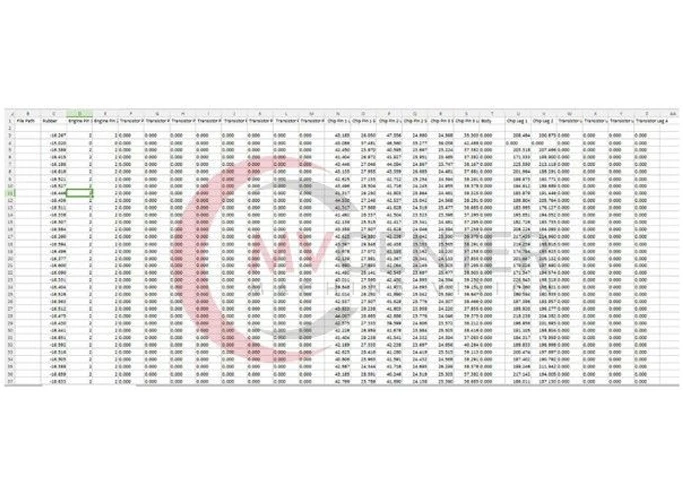

Report of inspection results of the control system.