The system’s task is to control the correctness of the safety puncture used in insulin delivery devices,

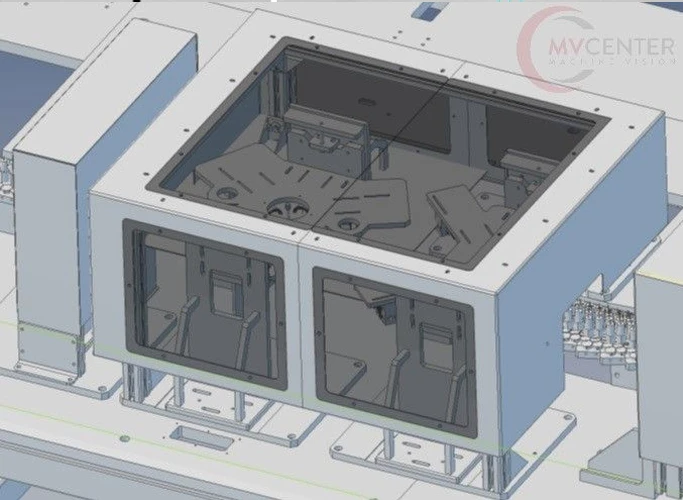

At the various stages of production. The system consists of 3 workstations that inspect 20 workpieces on a pallet simultaneously. The stations are set according to the position on the machine:

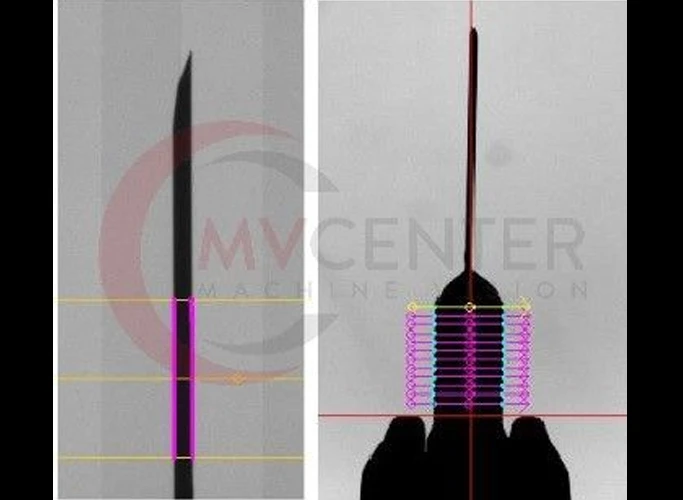

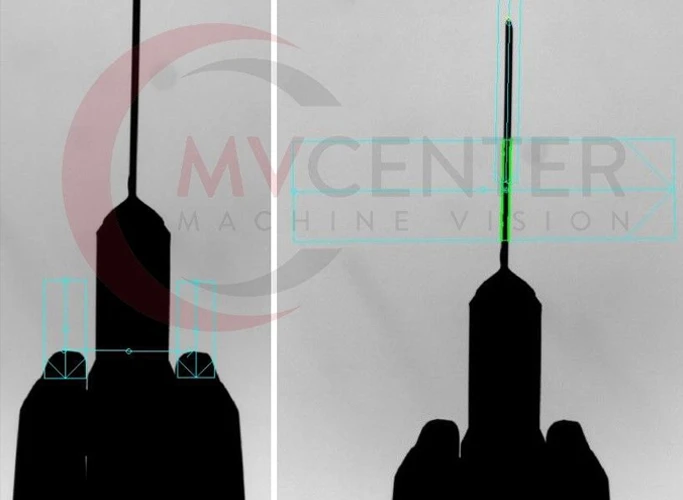

- Station 1 – cannula height control, cannula tilt, efflux control

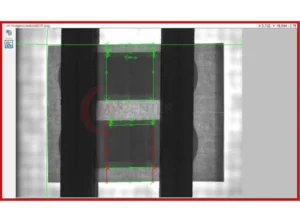

- Station 2 – inspection of the spike of the cannula – detection of the so-called “hooks”

- Station 3 – glue check, glue check on body, glue detection on cannula

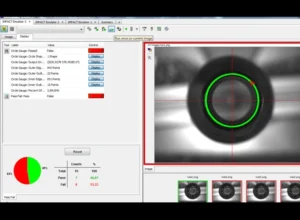

The system is equipped with an operator panel that allows, among other things. for displaying inspection results with pictures taken, displaying statistics (overall, individual nests or pallets), displaying pictures of rejected pieces or making changes to vision inspection settings.

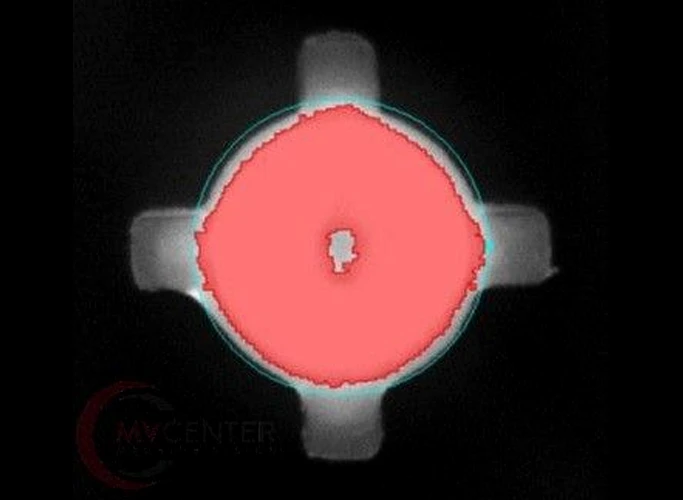

Body and cannula detection.

Determination of cannula inclination

3D model of the thread inspection station.

Glue detection on the body.