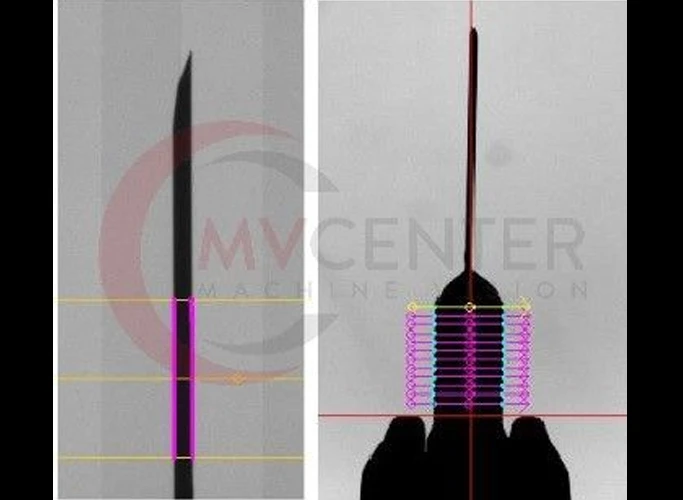

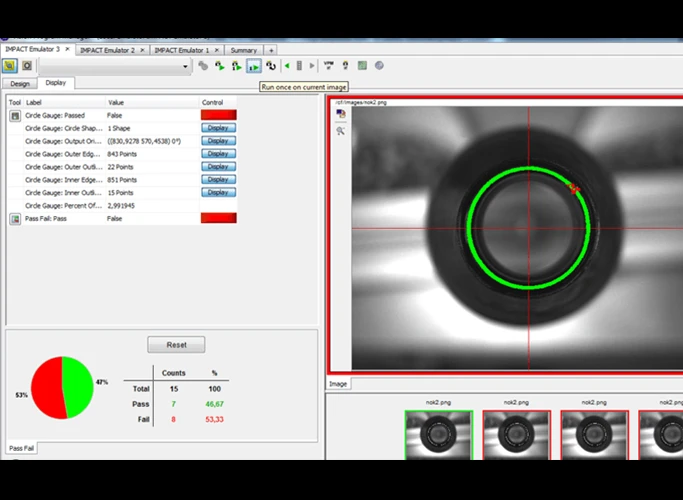

We present to you one of the applications made by the MV Center Vision Systems Company using 3D technology. The described project consisted of hardware selection, inspection software and integration of the vision system into the production line.

Aim of the project

Quality control of the installation of the gasket on the plastic component (car door handle component).

Type of inspection

- 3D measurement – position of the gasket relative to the plastic base,

- 3D scan-based detection – distinguishing component types based on markings;

Project details

The application involves checking the correctness of the assembly of a plastic component with a gasket, at two assembly stations within a single station. Elements such as:

- Checking the presence and correctness of the tightening of the gasket lugs on the plastic piece,

- Checking the correct adhesion of the gasket to the plastic part,

- Checking the presence and proper tightening of the plug mounting clip,

- control of the presence and type of plug, depending on the selected reference,

- Checking the compatibility of the symbols placed on the plastic component and the gasket with the symbols set in the reference.

Main challenges

- Detection of black seal on black plastic,

- Cycle time < 8 seconds;

Hardware solution:

- ECCO Smart Ray 3D line scanner,

- Zebra Aurora software;

Scope of the project:

- Tests on customer samples and selection of a solution,

- Project for the installation of a Video System inside a workstation,

- Inspection software in the Zebra Aurora environment (Adaptive Vision Studio),

- User Interface Software,

- Supply and integration of 2 SMART RAY ECCO scanners,

- Assembly, commissioning, testing, validation

- Service training,

- System documentation,

- User technical support provided remotely;

Design details

| Year of implementation: | 2022 |

| Project result: | elimination of the risk of complaints thanks to 100% control of manufactured components |

| Payback time: | 15 months |

The project budget is affected by many variables, hence if you are interested in a similar solution, it is best to contact us ↓.

Project lead person:

Paweł Janczyk

pjanczyk@mv-center.com

669 209 109