A system for vision inspection of a shock absorber was constructed for one of the largest manufacturers in the automotive industry.

The inspection is aimed at:

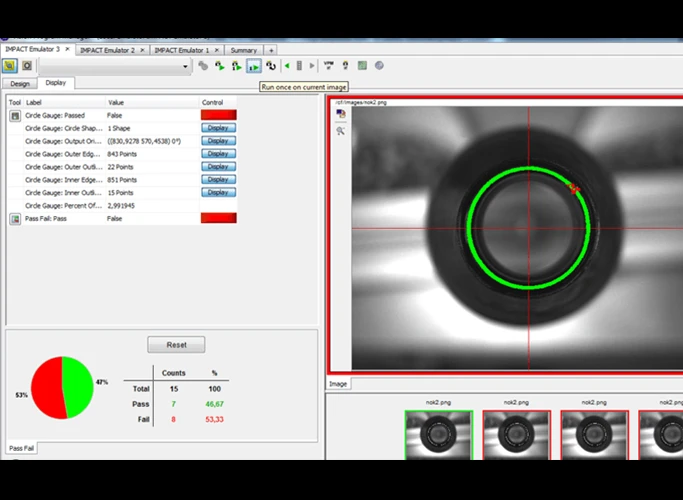

- distinguishing between types of shock absorbers,

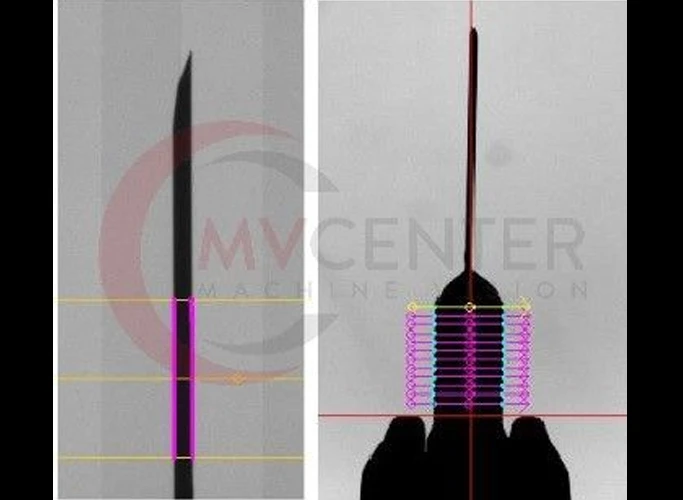

- determining the correctness of their assembly,

- reading the codes on the label,

- label position,

- the position of the layout and all required elements on the label.

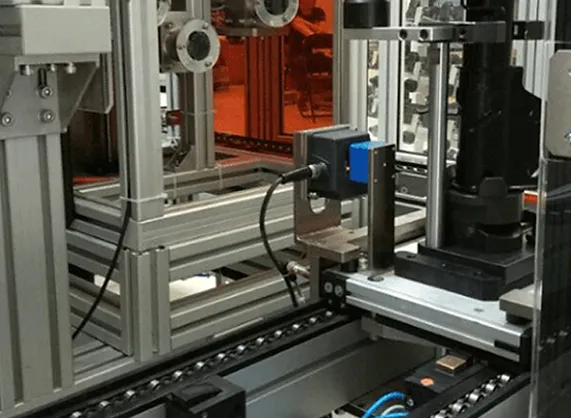

The entire shock absorber is controlled by 4 independently operating cameras integrated with a vision processor.

Vision inspection of shock absorbers