Mr. Ford would be proud of us.

Widely regarded as the father of industrial mass production, Henry Ford had a habit of personally inspecting every automobile that rolled off the belts of his factory. He signed it with his own signature, which illustrates well his almost obsessive attention to the quality of the legendary Model T.

When production began to accelerate, the brilliant visionary had to abandon the ambitious procedure, of course, however, customers appreciated the quality of this simple car.

Thus was born the legend of the brand, thanks to which America shifted from horses to cars, and entrepreneurs became convinced that a mass product could be offered at a low price and good quality.

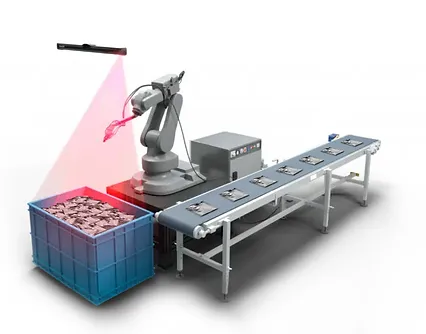

After more than a century, the “the Lord’s eye fatteneth the horse” method has been replaced by an electronic eye aided by artificial intelligence,

and we know what to do so you can blindly sign off on every product that leaves the walls of your company.

The origins of machine vision.

The idea of machine vision was born in the late 1940s/early 1950s with research on artificial intelligence, when the U.S. military began using image analysis. However, the practical application of the nascent concept of applying it to industry had to wait until the 1960s.

1970s.

The 1970s saw a breakthrough in machine vision. The Massachusetts Institute of Technology developed an image analysis system that would eventually control a robotic arm for industrial applications. In 1966, MIT’s Marvin Minsky asked his student Gerald Jay Sussman to spend his summer vacation trying to connect a camera to a computer, and so a mathematical description of what the camera’s eye captures was born.

1980s.

In the 1980s, linking the pyramid of images made it possible to search for congruent parts of them, and subsequent versions of the pyramids also made it possible to locate scaled objects. Thanks to algorithms that reduce image analysis time, it was possible to apply machine vision on an industrial scale.

Repeatability of measurements, and increasing product quality requirements have made machine vision the basis of many production lines.

In addition, in addition to constantly developing algorithms for existing methods of creating and programming machine vision, new methods were being developed, such as.

- photostereoscopyrelying on the analysis of several photos under varying lighting conditions,

- The “shape from shading” method of using the relationship between the amount of reflected light and the third dimension,

- The “shape from focus” method of using the relationship between image focus and the third dimension.

1990s.

The 1990s saw tremendous growth in the machine vision industry, driven by technological advances in computer design. Integrated circuit processing made it possible to make smart cameras that could not only collect image data, but also extract information from the resulting images, without using a computer or other external processing device.

With more powerful computers, it was possible to introduce developed mathematical formulas into image analysis to help obtain 3D image models.

At the end of the 20th century, scientists speculated which direction was most likely for the development of machine vision (machine vision)

and the assumptions of researchers at the time, seem to be still relevant today.

David Marr in “Vision: A Computational Investigation into the Human Representation and Processin” included three levels of machine vision development:

- Computational theory: what is the purpose of doing computation? What are the limitations and how to deal with them?

- Representation and algorithms: what is input, output, intermediate information, and which algorithm to use for calculations,

to get the desired results? - Hardware implementation: How do representations and algorithms transfer to existing hardware?

21st century.

We now know that the problem of machine vision is much more complex than MIT researchers thought in the 1970s. Early attempts to obtain 3D models were based on extracting edges in 2D space, and using a block model. At the end of the 20th century, research into edge detection algorithms was a milestone in the field of machine vision. Research has also been conducted on modeling objects with shapes other than polyhedrons, such as cylinders. It was also noted that to create a 3D model can be used:

- stereoscopic vision,

- shadows,

- and light intensity.

Due to technological advances, machine vision on production lines has ceased to be just an idea in R&D and is now widely implemented and used in the manufacturing industry for applications including quality verification and product inspection.