We present you with a description of the inspection of a vision system for hot and cold beverage lids. The application’s task is to detect and eliminate contaminated or dirty lids.

The use of biomass is associated with a much larger number of inclusions of very different colors and shapes. The project described here consisted of selecting equipment, designing components, creating inspections, and integrating the whole thing into an existing lid-making machine.

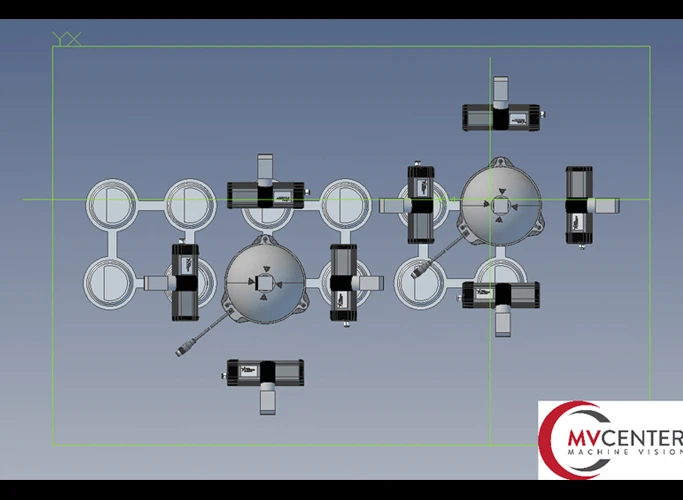

Due to the machine’s design, the vision system consists of twin systems, where each is responsible for inspecting two rows of product. Each of the lids is controlled from the top and from each side, allowing 100% coverage of the top and sides of the product. LED illuminators with a blue light color are responsible for proper illumination, which, combined with the characteristics of the defects, significantly improves their visibility. A pack of 6 inspected lids passes under each camera in about 1.2 seconds. The aptly selected components together with Adaptive Vision Studio software allowed the integration of a reliable inspection that controls the manufactured part.

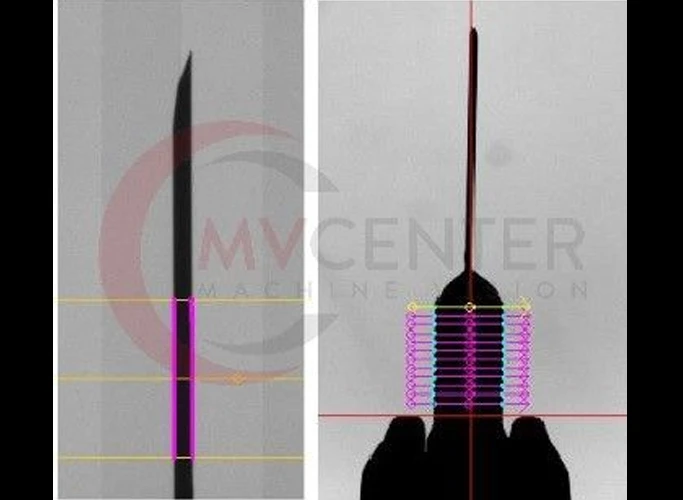

Detection of inclusions on lids.

Schematic of a vision system for inspecting inclusions on lids.

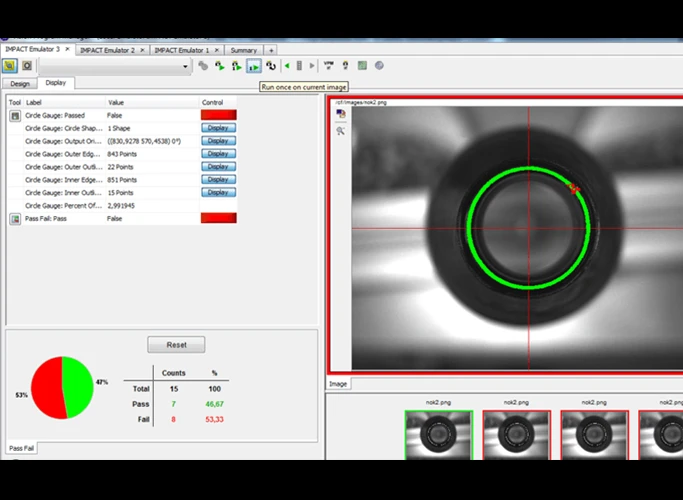

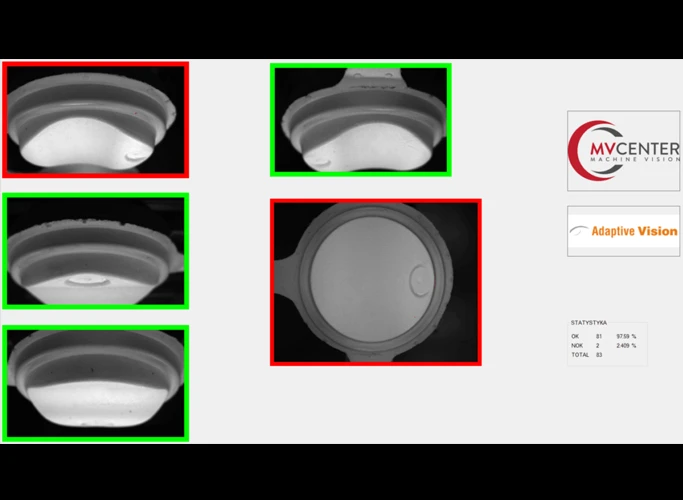

Control of inclusions on lids – user screen.

Control of inclusions on lids – user screen.

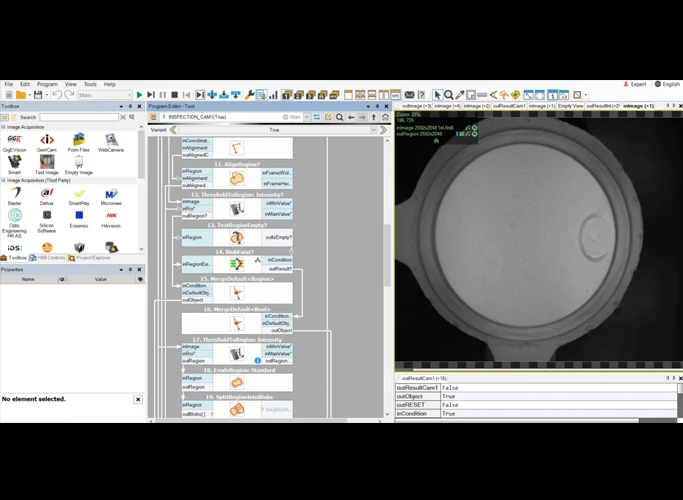

Algorithm for detection of inclusions on lids.