Homepage » Design of vision systems

Based on the requirements you provide and information about your product and production process, we will carry out a technical analysis and prepare and implement a solution to avoid complaints and generate savings.

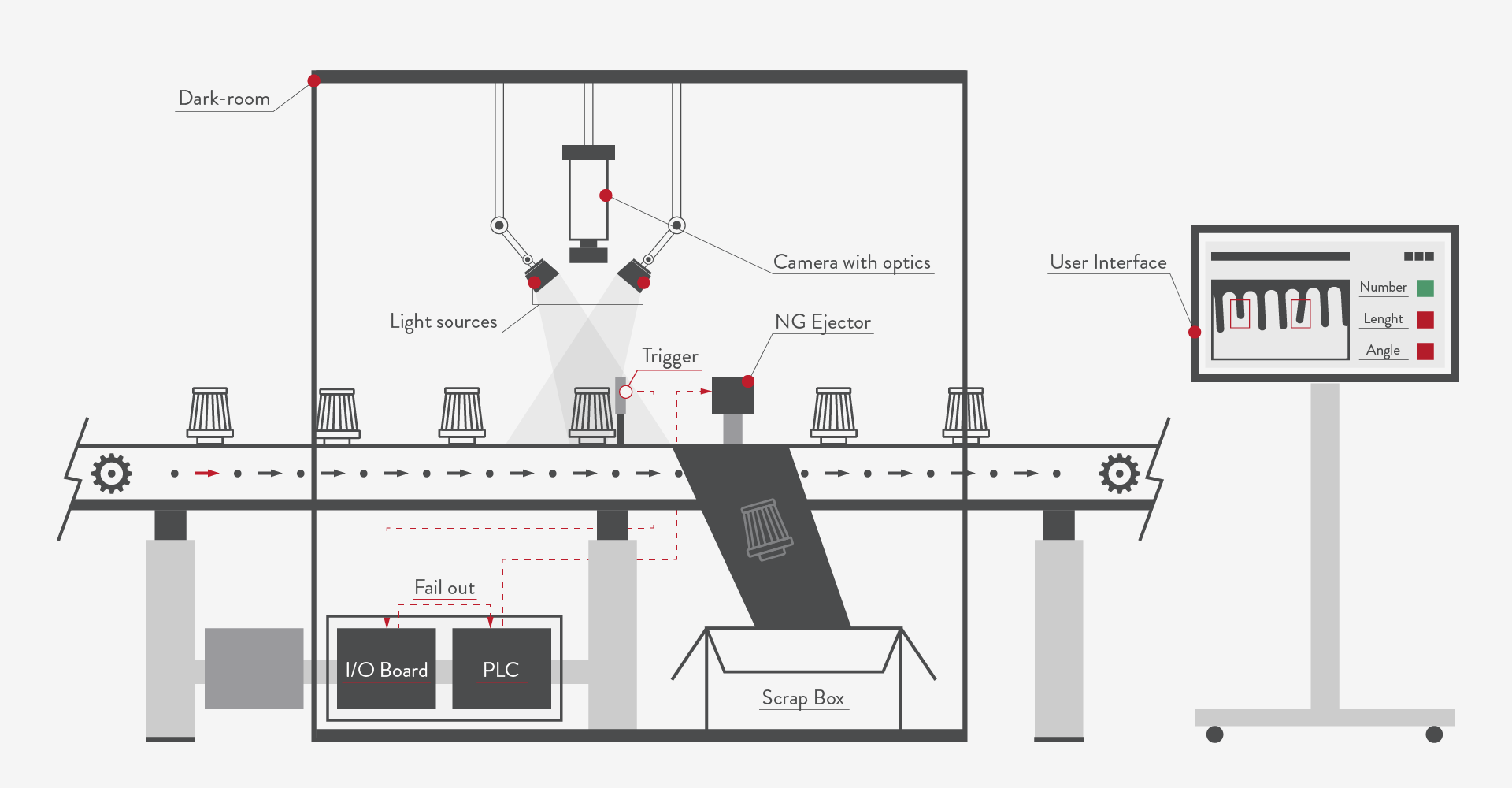

Vision systems in production, or AOI (Automatic Optical Inspection), are devices equipped with cameras or scanners that inspect each product on the line on the basis of the images/scans taken and automatically eliminate non-compliant ones from the process.

This avoids complaints, reduces handling costs and prevents the unnecessary processing of non-compliant products, leading to savings and increased customer confidence.

The process of selecting a design and implementing a vision system to suit a customer’s needs requires several stages. Having completed more than 200 projects in a variety of industries, we know how to guide such a project to a successful conclusion. Details can be found below.

At this stage, a suitable control solution is selected on the basis of the specifications provided and the information collected and tests carried out.

Then, the design of the vision system is developed together with the control, the NOK ejection system and other peripherals.

After assembly of the control system and acceptance at the MV Centre (FAT) site, the system is transported to the customer’s plant and then installed in-line and integrated into the master system.

The position is then debugged on a large volume of product to achieve the target performance parameter (usually min 99%).

This stage is completed with acceptance (Final Acceptance).

Once the system has been commissioned, staff training (operators, technologists and UR) is carried out.

MV Centre systems are covered by online technical support with a rapid response time, allowing the user to be retrained during the first weeks of operation.

Below, we detail the process that results in a dedicated vision system implemented in your company.

We have installed more than 200 vision systems in various manufacturing industries. Our systems have already saved our customers millions by avoiding complaints and gaining savings from early NOK detection.

The average project duration from order placement is approximately 18 weeks.

Dozens of profitable implementations among manufacturing companies allow us to highlight many recurring benefits.

Controlling the product at the right stage leads to a reduction in production costs, and also avoids losses due to complaints.

A photo record of the product ID allows you to demonstrate that the product left your plant in a condition that meets the customer’s specifications.

You can get control of any product even with fast production in a reliable and repeatable way (we’re talking seconds and milliseconds here).

Fast remote service and access to logs allows you to get support almost immediately after a request.

Increase capacity on manual assembly lines (moving people from inspection to assembly).

In an era of staffing problems, a vision system is “trained” only once.

No one wants to take on manual inspection because it’s a tedious task – machine vision doesn’t question the work.

A vision system is a proof of quality – some companies require it to work with you.

Take 5 minutes to see how long it takes to recoup your investment in a vision system. Calculate how much you can spend on automating the quality control process to achieve the required ROI.

The most common vision systems we design are used in inspection:

In addition to the inspection itself, we offer systems for reporting results and photos to PDF (protection against unjustified complaints), as well as graphs of statistics and trends, so that the production process can be monitored and improved.

We realise inline and offline vision systems. Our solutions are based on cameras and 3D scanners from leading manufacturers (Keyence , Cognex , Sick, LMI, Zebra). Information about our partners can be found here ⟶. [link do sekcji partnerzy]

The design of the vision system is based on three key considerations, such as:

This approach means that the solutions offered are tailored to the production line and can be an integral part of it. Where it is not possible to install controls in the line, it is possible to supply an offline station.

We support manufacturing companies and process and quality control engineers at dozens of factories of companies such as:

Controlling the product at the right stage leads to a reduction in production costs, and also avoids losses due to complaints.

In the pharmaceutical industry, we usually inspect the correct printing of the LOT number and expiry date and the quality of the packaging (bottles, blisters) as well as the product itself (needles, capsules, tablets).

In the plastics industry, inclusions, closure quality and shape are the most commonly inspected.

In the electromechanical segment, the most common applications are assembly, dimensional and marking inspection.

In the packaging industry, the most common checks are the completeness of the products in the packaging, the correctness of the closure and the content and position of the labels.

In other industries, we carry out inspections of shape, colour, completeness, surface quality, orientation, material defects and many other parameters, depending on the specifics of the product.

Find out how we solve your problem with the help of machine vision

If you are not sure whether machine vision can help solve your problem – just ask! It costs nothing and our technical team will analyse your product, its production process and the scope of the inspection.

We will get back to you within 24 hours. For 80% of enquiries, we send you a free analysis of the problem and a price and technical proposal to solve it within 7 days, allowing us to verify the ROI in the first stage.

Copyright © 2023 MV-Center / Made by NEXT