Homepage » Services » Ready-to-use vision solutions » Automatic quality control station for candle holders

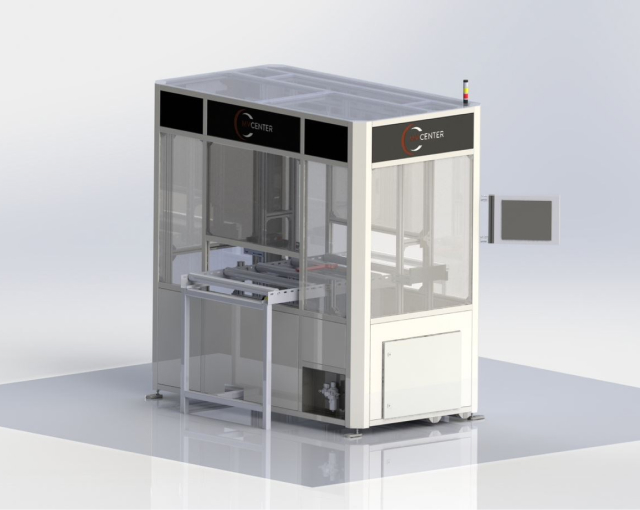

The solution developed by MV Center is designed to control the height of the pour and the length and wick seating of the candle refills. The solution can be implemented in an existing production line or supplied as a stand-alone version with its own built-in transporter.

The ejection system eliminates defective products before they reach the packaging process thus reducing unnecessary downtime and eliminating complaints. The solution is equipped with a product separator and, thanks to its intuitive changeover system, can be used for multiple references.

Thanks to the serial error function, it is possible to stop production when a user-defined limit is exceeded.

Intended for contributions: | |

|---|---|

Diameter | 50-100 mm |

Height | 40-300 mm |

Weight | up to 500 g |

Container colour | any (transparent and non-transparent) |

Production process parameters | |

|---|---|

Performance | up to 11 000 pcs/h |

Maks. pręd. przenośnika | up to 6 m/min |

Work environment | room temperature in the range +10/+45°C, humidity up to 80% |

Controlled parameters | any |

Performance | up to 11 000 pcs/h |

Controlled parameters |

|

Available soon

Available soon

We help control and improve production processes reducing errors with the help of machine vision. We will design and implement a (cost-effective) vision system designed specifically for your particular product and fine-tuned for your production line.

Copyright © 2023 MV-Center / Made by NEXT