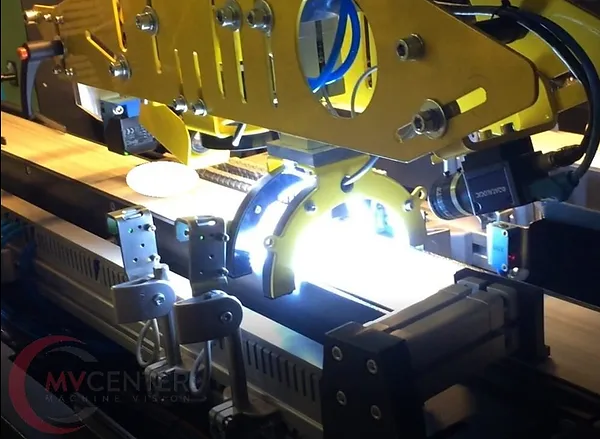

For one of the largest rubber processing factories in Poland, a complex station was made for sorting 16 different products consisting of rubber, plastic and steel/aluminum components.

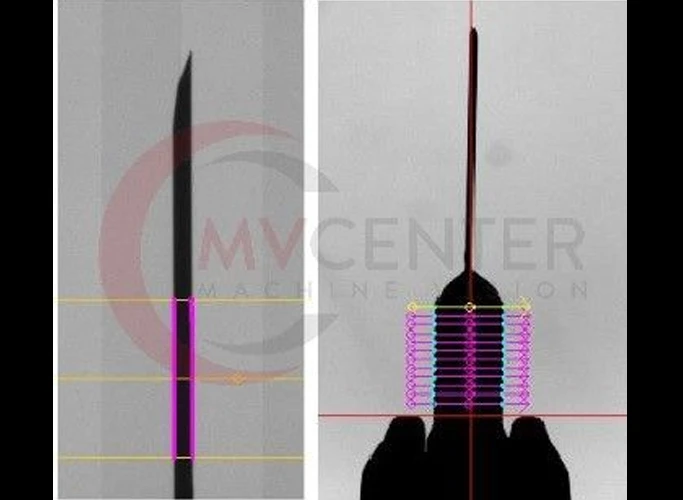

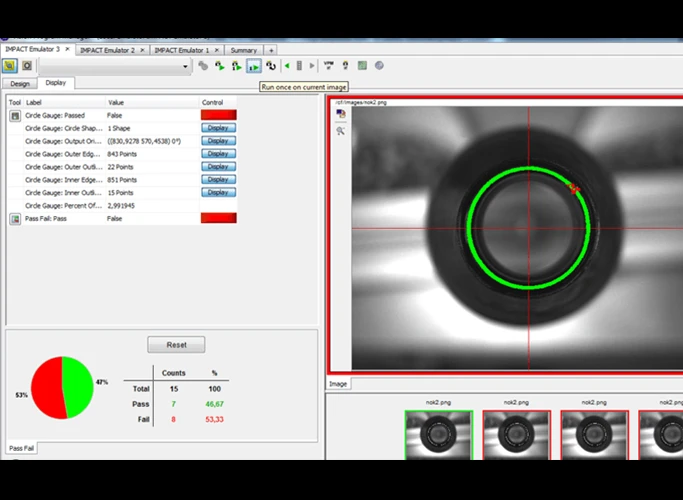

The equipment is designed to sort through all the pieces and separate them according to set parameters, as well as inspect them for type and the presence of defects.

If a defect or the wrong type of workpiece is detected, it is rejected. The entire process from backfilling is automatic.