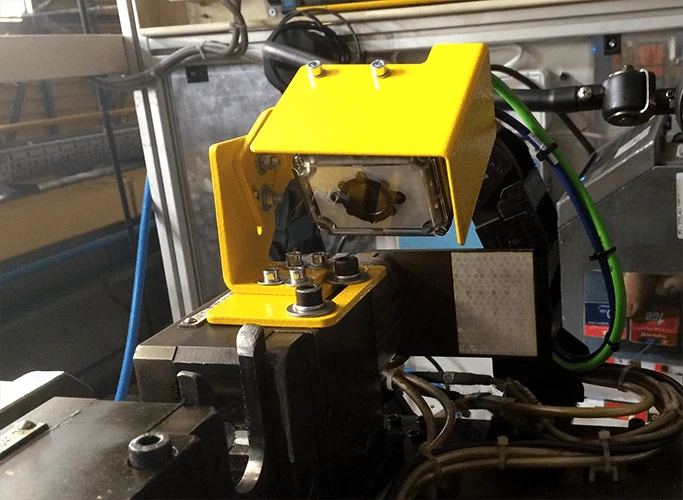

In April 2018, a project involving the implementation of two vision inspection stations for a rubber gasket was implemented. The gasket is located on a component that is part of a car’s suspension.

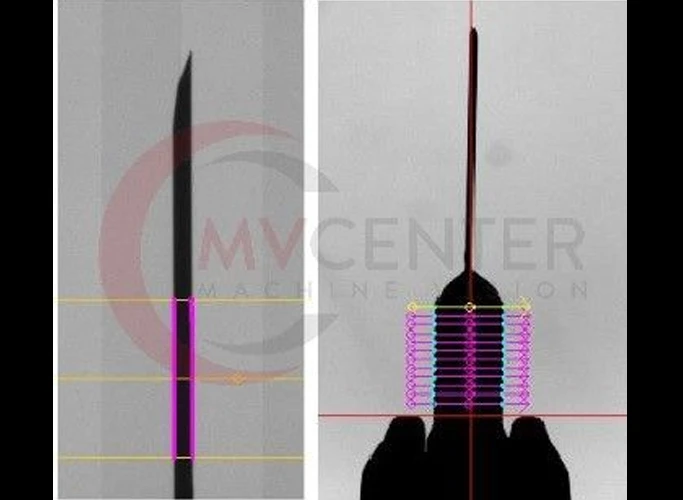

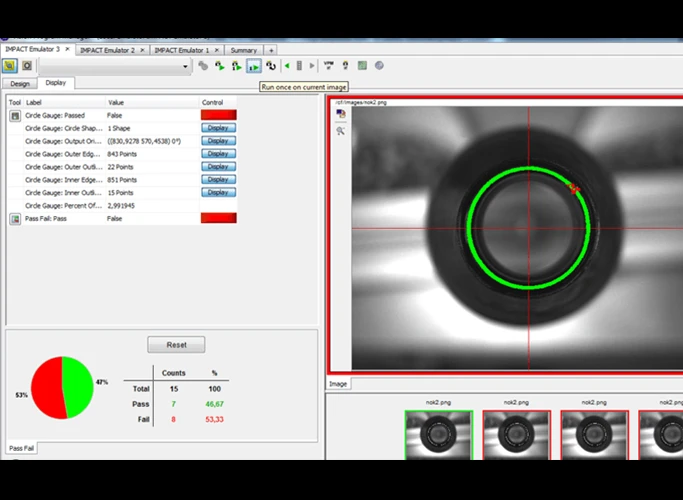

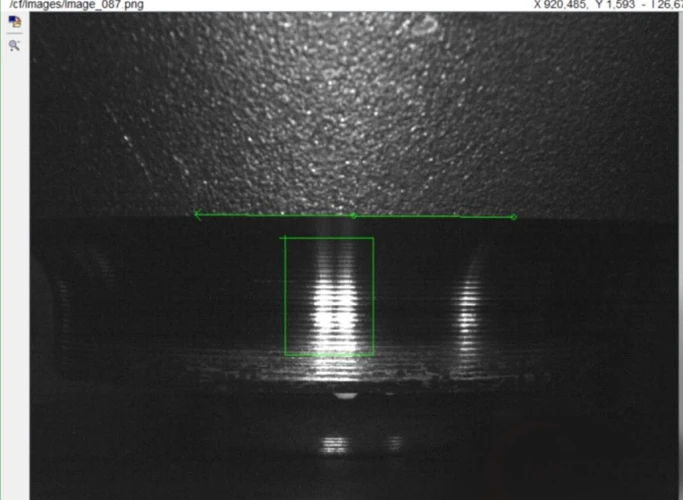

The vision system detects the presence or absence of a seal, depending on the reference (manufactured type).

If a discrepancy is detected, the defective workpiece is discarded.

The automatic control solution used allowed the customer to speed up the production process and eliminate complaints.

DATALOGIC P10 camera

Seal presence detection

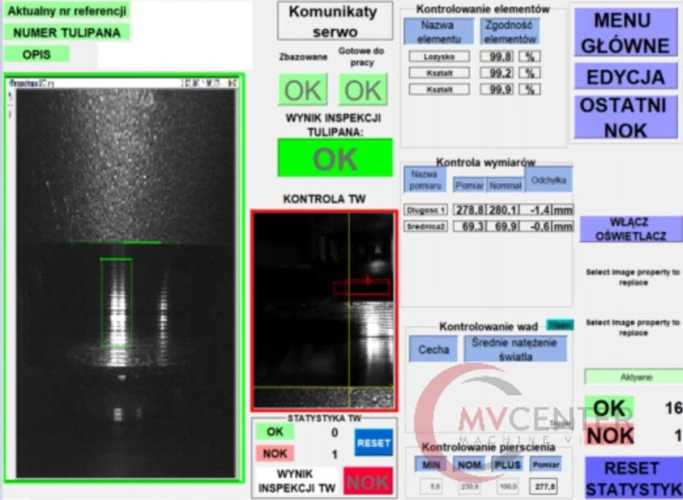

Video system operator interface