Control you can trust.

In a free market, the key to a brand’s long-term success is the high quality of its products.

The problem of its effective control becomes particularly acute when “manual” methods of control no longer work. Industrial production methods produce a lot, quickly and with reproducible quality, so they need equally effective quality control tools.

Modern technology makes it possible to automate quality control processes, performing their tasks more accurately, faster and cheaper than the best-trained personnel.

Its crowning achievement is machine vision.

Hungry for knowledge? Learn about the history of machine vision

and find out why Henry Ford signed each car with his own hand before it left his factory.

How does it work?

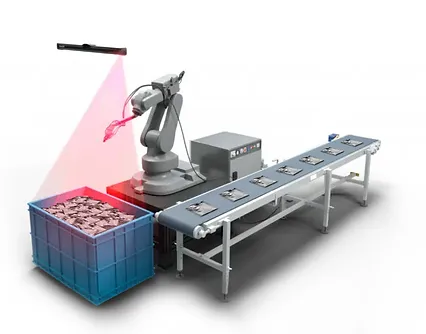

The backbone of most machine vision systems are image capturing devices (cameras or scanners) and a computer that analyzes the data they send.

Dedicated software processes the incoming images in real time and catches deviations from the standard assumed for the item.

Illuminators are also an integral part of the system, providing the cameras with optimal working conditions.

Completing the whole are usually automatic ejectors or other peripherals that remove items identified as non-conforming (NOK) from the production line, eliminating them from further processing, making it autonomous.

Interestingly, while the effectiveness of a quality control worker declines over time

due to purely biological considerations, then the efficiency of machine vision is constant (systems based on image processing algorithms) or even increases (in the case of systems based on machine learning).

Machine vision can be expanded to a comprehensive system that not only controls the quality of the items being inspected, but also controls the packaging and palletizing processes by cooperating with external equipment such as robots, processing machines or labelers.

Working in three dimensions.

Three-dimensional objects pose entirely new challenges to machine vision – processing a cloud of millions of points and working on multiple planes is a much more difficult task than analyzing 2D images, especially in an efficient industrial production environment.

Today’s solutions based on linear and structural scanners are able to keep up with production and control in-line shape, dimensions , geometry and also, for example, the completeness of parts.

3D scanners also allow automation of depalletization processes and are increasingly used in automated warehouses.

Where will a vision system work best?

Where will a vision system work best?

Despite hundreds of deployments over a dozen years, the possibilities of machine vision applications continue to surprise us. In addition to large industries, we have found a way for machine vision to serve customers in less obvious industries, such as candle production on a scale of millions. Machine vision will work anywhere:

- It produces a lot and quickly.

- A quick and flawless quality assessment of the product is essential.

- Priority is given to the safety of product use and the omission or neglect of a process, can have serious consequences.

- The cost of processing a nonconforming item is high and deficiencies must be eliminated from the process as early as possible.

Some of the industries where machine vision works best:

- automotive

- pharmaceutical and medical industry

- cosmetic

- plastics

- electronic

- packaging

- food and processing

What else besides a quick ROI?

The basic criterion in the design of our solutions, is the shortest possible ROI achieved by the client.

However, a quick return on investment is not the only benefit to the customer. However, a quick return on investment is not the only benefit to the customer. The elimination of shortages from the market over time translates into an increase in the value of the brand as a reliable producer of quality products, which is an invaluable added marketing value.