A project involving two PET bottle inspection stations has been implemented at a leading beverage manufacturer.

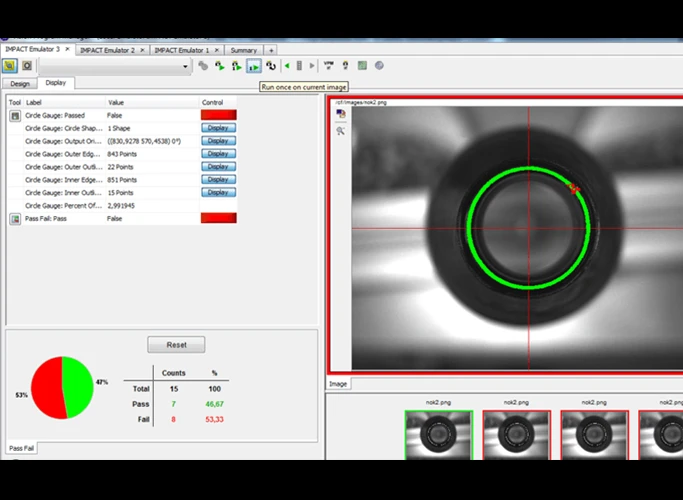

Station one inspects the presence, position and correctness of the tightening of the cap, as well as the presence and quality of the retaining ring. This position also controls the level of brine in the bottle.

At the second vision inspection station, the presence, type and position of the label on the bottle is checked using a multi-camera system. An interesting solution is the automatic height adjustment of the station relative to the selected reference.

Both stations are integrated into the production line. They are equipped with a multifinger ejector, which moves defective bottles onto a shortage conveyor without tipping. The whole thing is made IP67 sealed, and the capacity is 20,000 bottles per hour.

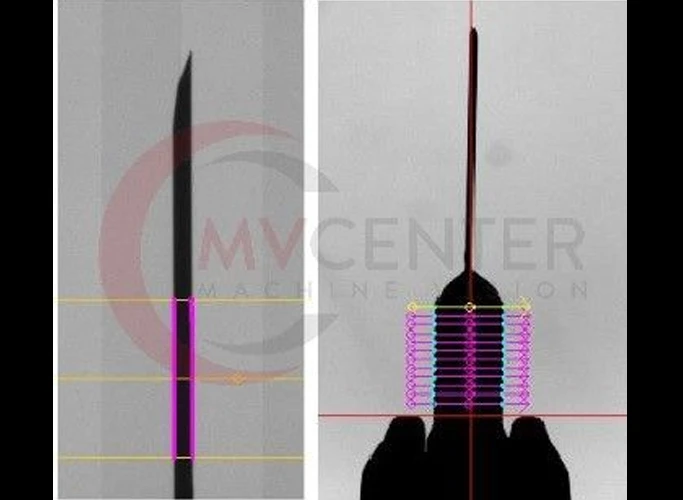

A vision system for inspecting the priming and capping of a PET bottle.

Control position.

Pneumatic Ejector (Multifinger)

Visualization of PET bottle inspection stations.

PET bottle inspection