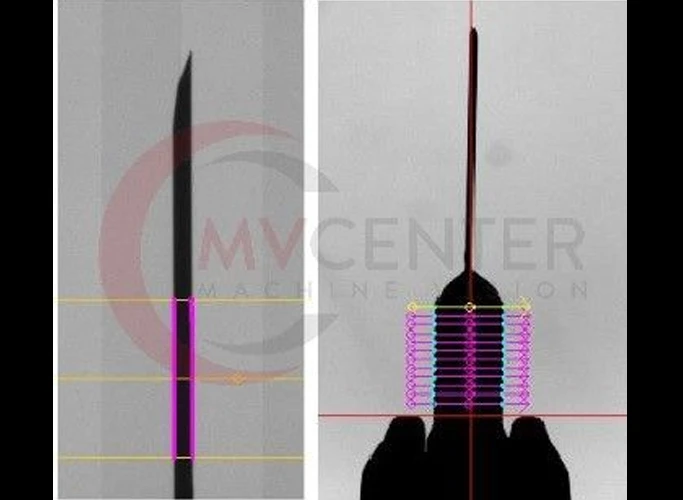

The task of the system is to inspect the surface of the Teflon strip before cutting to detect defects in the form of inclusions, holes, cracks and PTFE deficiencies. Detection of the above-mentioned defects results in marking the location of the defect with a marking head.

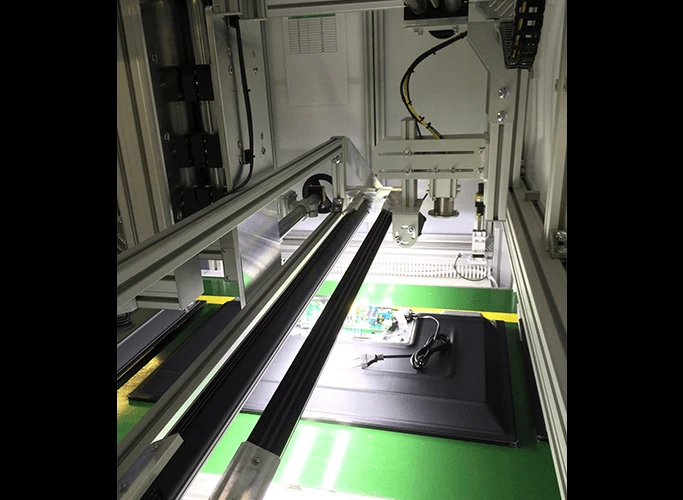

The tape marking system consists of two units:

- Tape inspection team

- Tape guiding and marking unit

A single inspectable image covers 100mm of tape. The camera uses signals from a bench-mounted encoder to build the image. The images are then analyzed using vision algorithms.

Detection of a defect on the surface of the Teflon tape triggers marking from the location with the defect over the next 200mm. The speed of tape travel for the duration of marking is reduced. Once the operation is completed, the speed returns to its normal value.

In order to operate the workstation in a convenient and intuitive way, 3 menus have been created on the touch panel: the main menu, the inspection mode menu and the menu for entering order settings.

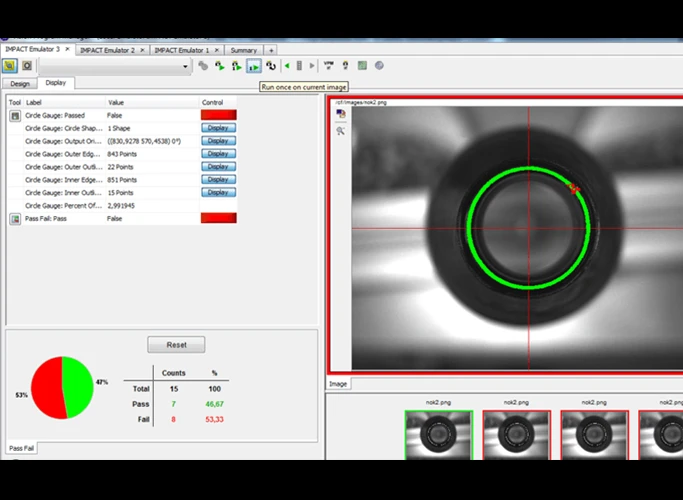

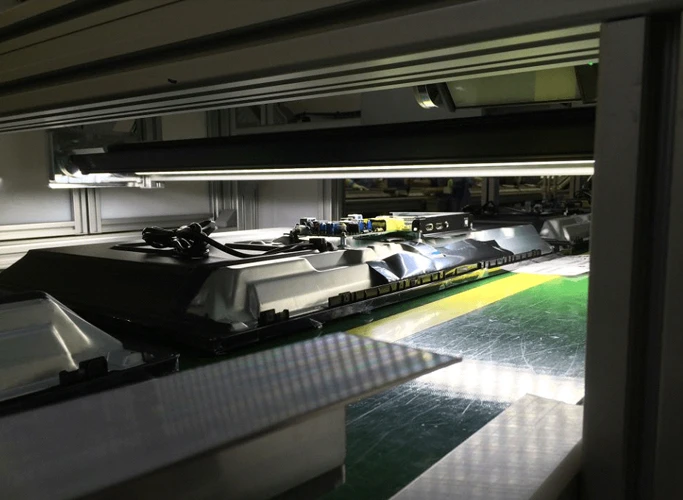

Video system station for inspection of TV receiver assembly.

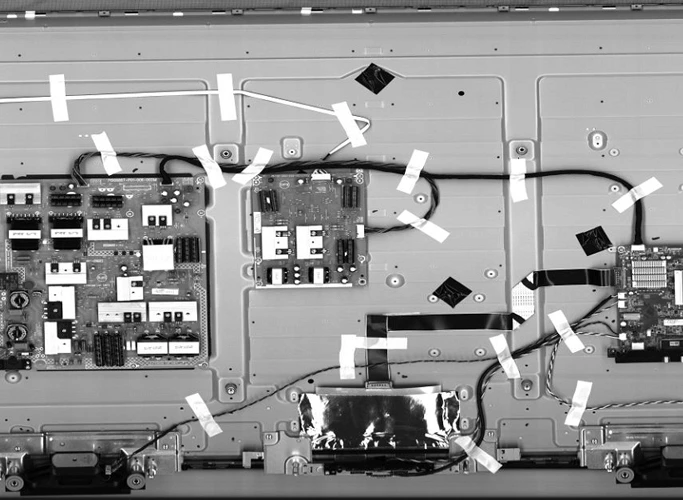

Scanned TV receiver.

Video system station for inspection of TV receiver assembly.