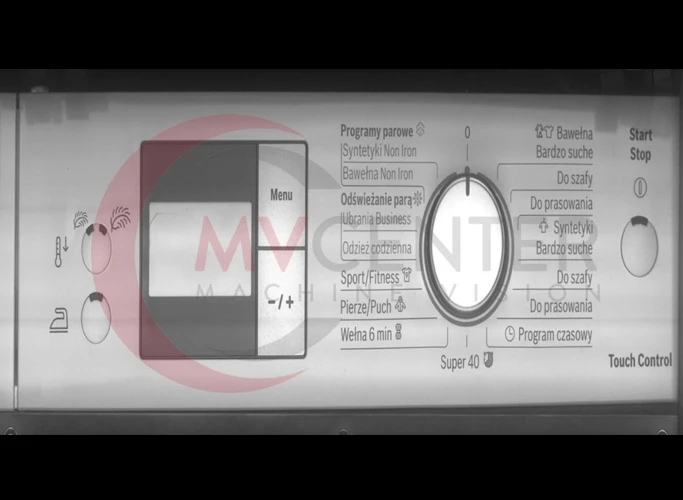

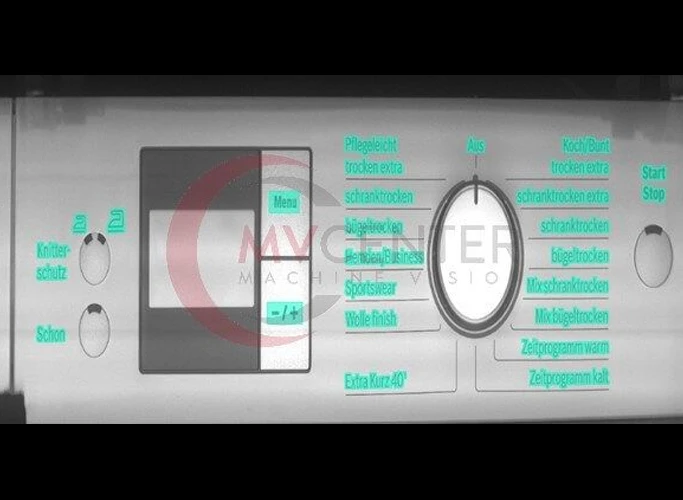

Application name: Inspection of printing and inclusions on household appliance panels. Scope of control:

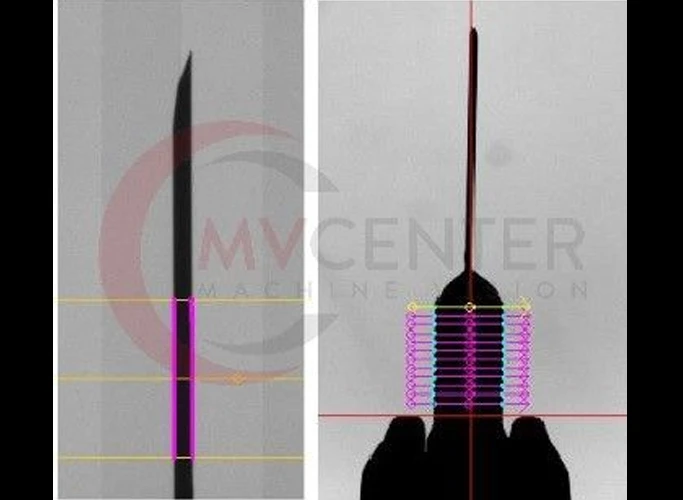

- control of inclusions (from 0.1 mm) on the panel material and in the display window,

- control of printing errors (overprinting) – defects , underprinting, smudged overprinting, inconsistent overprinting, wrong position of overprinting

Developing a panel print inspection application for the pad-printed home appliance industry is a challenge due to the huge number of different references and the small size of typical defects (inclusions, underprinting) – detection of defects with a size >=0.1 mm is often required. Therefore, at the hardware layer, it is necessary to configure the camera, optics and lighting in such a way that the resulting images are evenly illuminated over the entire surface of the panel (often irregular).

At the software layer, on the other hand, it is important to create a suitable development environment that will allow the user to intuitively add new references without lengthy programming. Panels are created in multiple versions both in terms of content and layout of prints (different hardware functions) and language (multiple versions of the same panel in different languages).

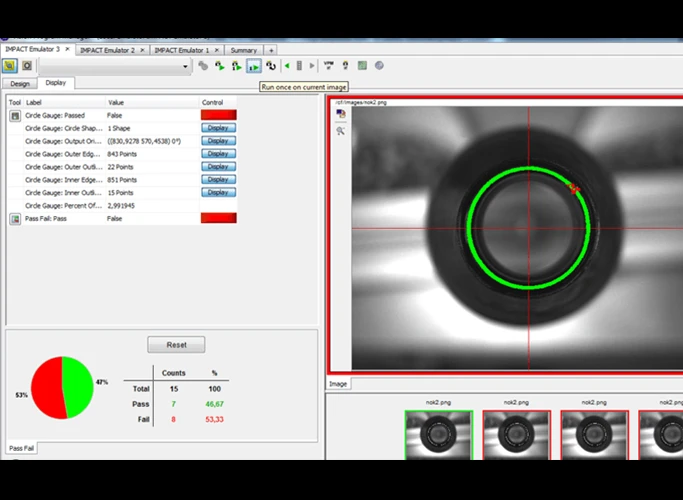

The presented inspection application for panels mounted in household appliances consists of several steps: the first task of the system is to read the QR code present on the panel and load the corresponding program (reference). The unique code of the cart is then read from the RFID cube on the assembly cart, to which the photo and inspection results will be assigned. The next step is to scan the panel (take a picture) with a line camera (this project uses a DATALOGIC M565 camera with a resolution of 4096 px in line) – the triggering of the picture is triggered by an optical sensor, while the signal for triggering subsequent lines is collected

from the encoder.

An inspection is performed on the image thus acquired and the data is stored in a buffer and assigned to an RFID code.

When the forklift enters the operator’s station, the forklift code is once again read and the buffer is retrieved from the buffer

and displayed the relevant data. The operator receives information about the inspection results and the defect information is displayed and marked on the operator panel. Once the barcode sticker is printed, it is read by the reader, and a report is saved containing all the data and inspection results.

Both the development environment and the operator panel are in Polish which makes it much easier to use

the application. It is also possible to choose a different language version.

With the remote monitoring and management system, you can easily connect to the station to check the system, change its parameters, service it or implement a new product without having to come to the customer.

Screen printing control.

Automatic print detection for quality verification.

Screen printing control – example of a defect (letter b)

Screen printing inspection – example of a defect (letter i)

Screen printing inspection – example of defect detection (letter c)

Screen printing inspection – example of defect detection (letter t)

Screen printing control on household appliance panels