For one customer, 3 vision control stations for 3D glasses used in movie theaters were created. Each station is equipped with 7 Datalogic cameras that are designed to:

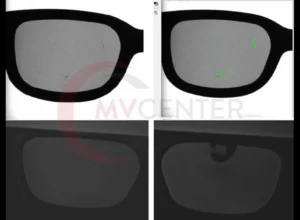

- inspection of scratches and mechanical damage to plastic eyeglass frames

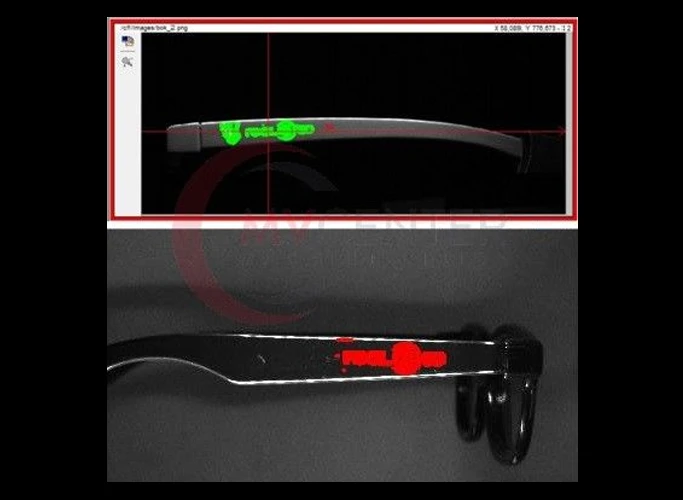

- quality control of the print/logo on each earpiece

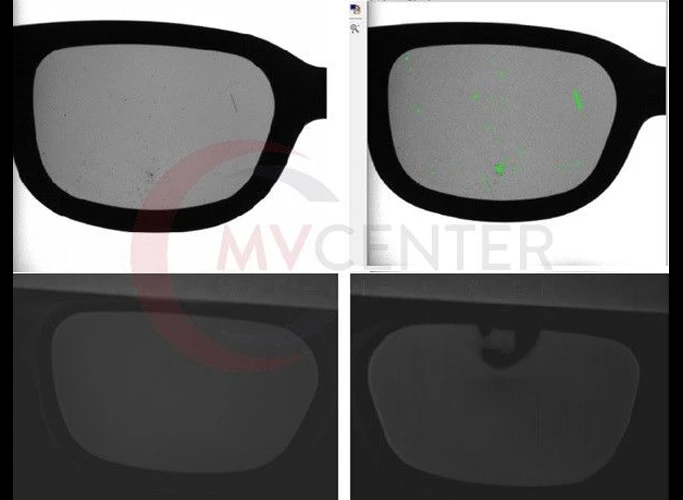

- inspection of damage / dirt / inclusions on lenses and frames (defects at the size level of 0.5 mm)

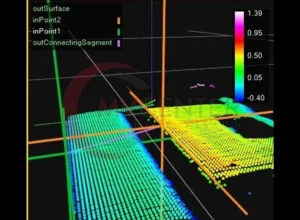

- control of curvature/deformation of eyeglass lenses (minimum 5mm diameter)

- control of the correct polarization of each lens

- checking the correctness of the installation of the temples (checking the breakage of the temple / its position and the angle of opening of the glasses).

The whole thing has been encapsulated in one compact and built-in workstation integrated with the customer’s conveyor belt. Inspection results are transmitted to the master control system and displayed on operator panels.

Eyewear quality control.

Logo Detection.