For our client, a manufacturer of dressing materials, we built a vision system to control the position of the nonwoven material on the patch.

The challenge we faced was inspecting 30 slices in one second!

The patches subject to inspection were flesh-colored, transparent and had prints.

The slices inspected were flesh-colored, transparent, and with different patterns printed on the surface.

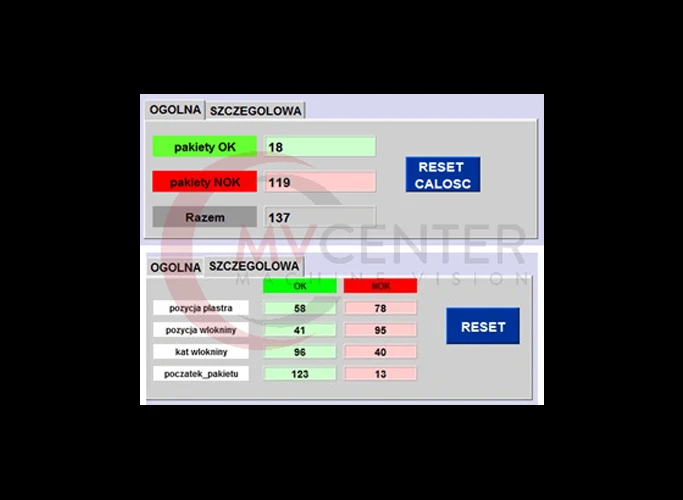

The system was developed with a very detailed reporting module including detailed statistics regarding:

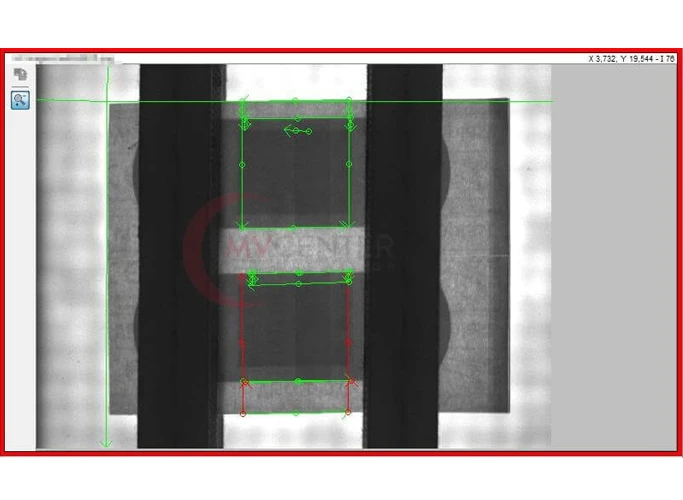

- Position of the slice – incorrect distance of the slice from the edge of the envelope

- Position of the nonwoven fabric – incorrect distance of the nonwoven fabric from the edge of the patch

- Angle of the nonwoven – nonwoven skewed beyond the tolerance (the angle is measured relative to the edge of the envelope)

- The beginning of the packet – an error when the system does not find the beginning of the packet or when the whole packet is very skewed or its position is disturbed

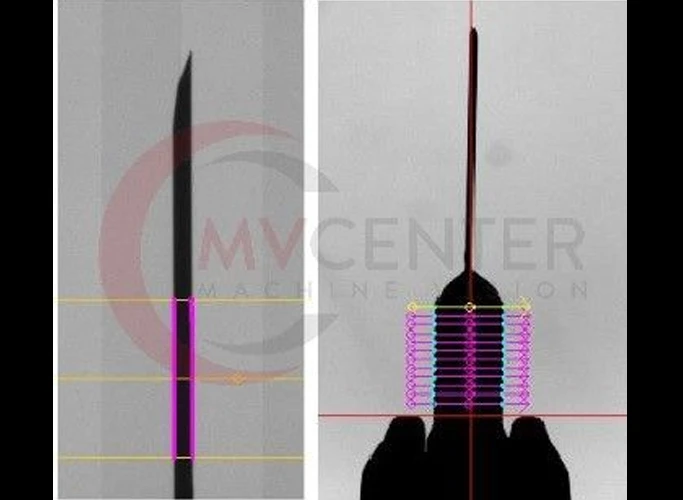

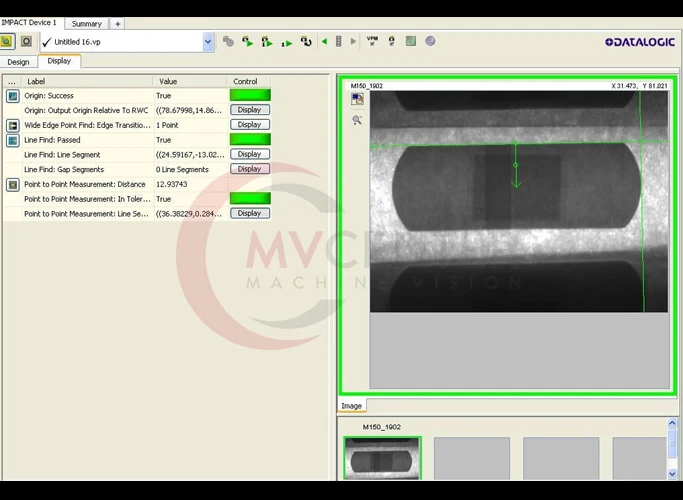

Slice detection – position control.

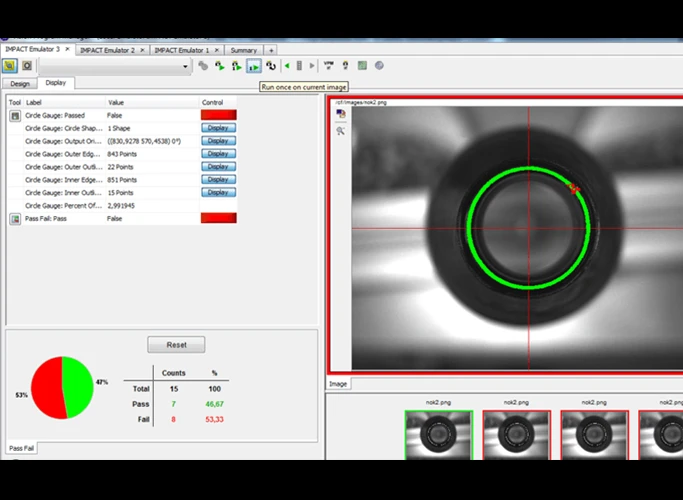

Quality control of slices.

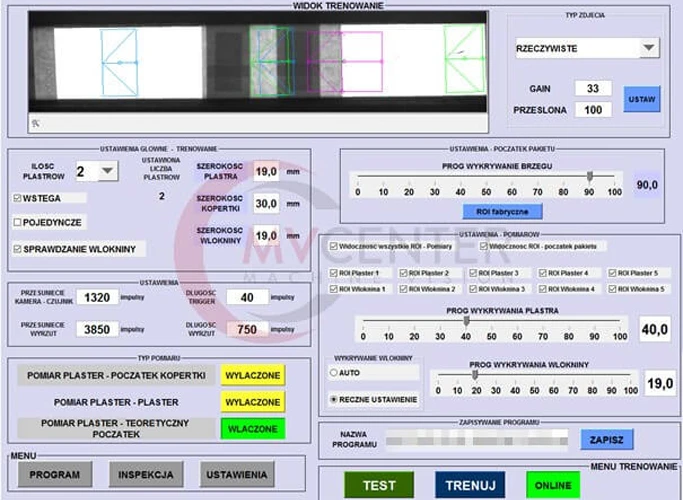

The user interface of the patch control system.

Control system statistics.