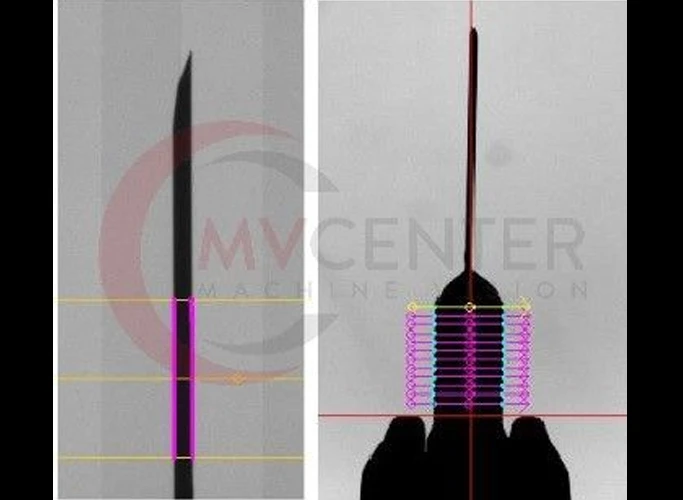

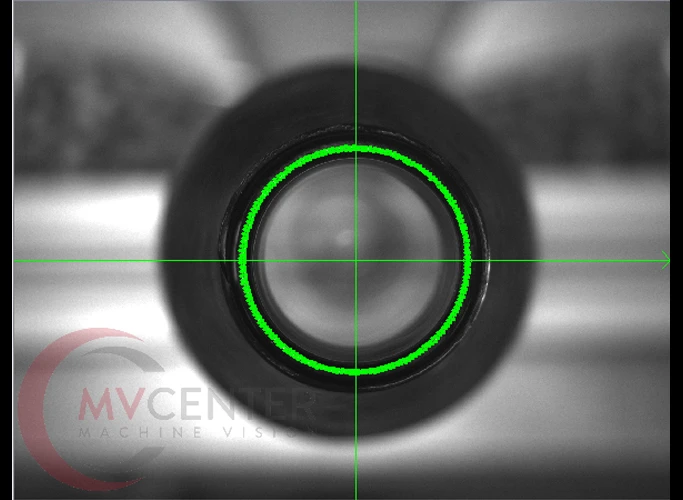

A vision inspection station for glass bottles was made for one pharmaceutical company. Inspection involves inspecting the top surface of the bottle neck, where cavities/chips or distortions often occur, preventing the final product from being properly sealed.

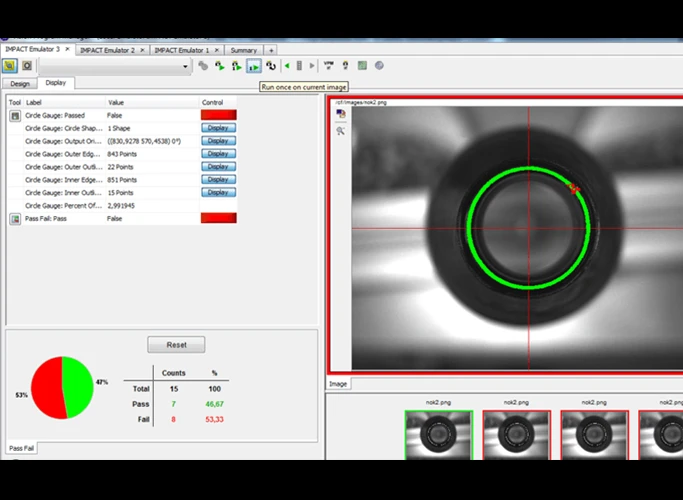

The multi-camera vision system successfully detects and uses a pneumatic ejection system to eliminate defective pieces from the assembly line.

User panel – home screen.

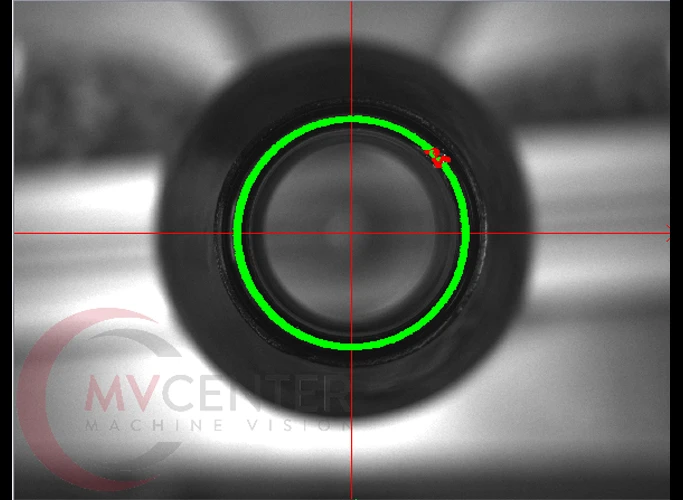

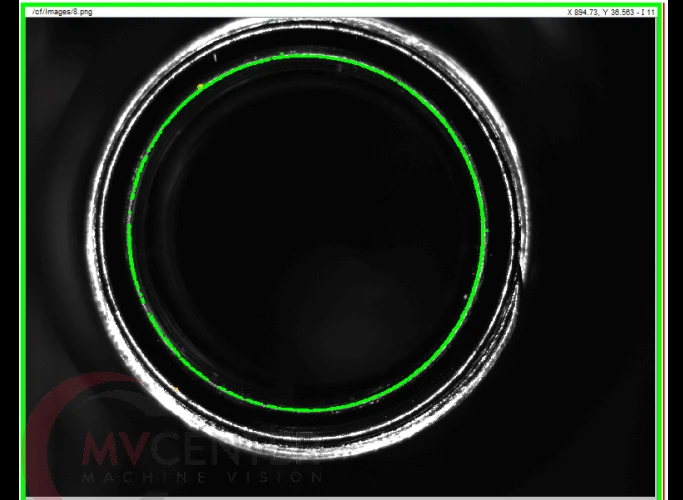

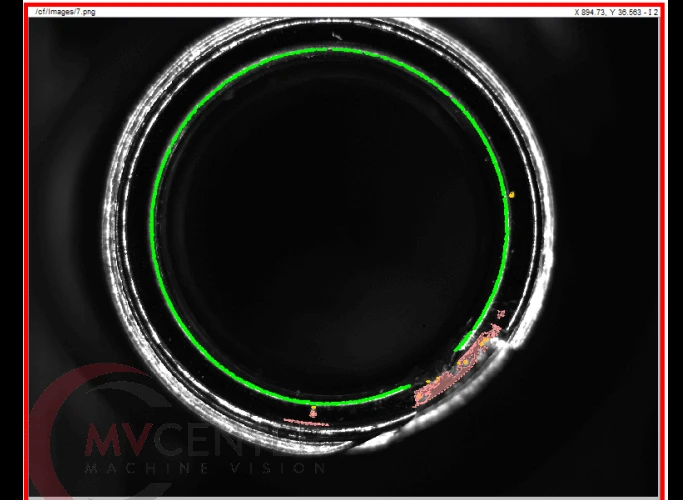

Damage control of glass bottles.

Damage control of glass bottles.

Damage control of glass bottles.

Damage control of glass bottles.

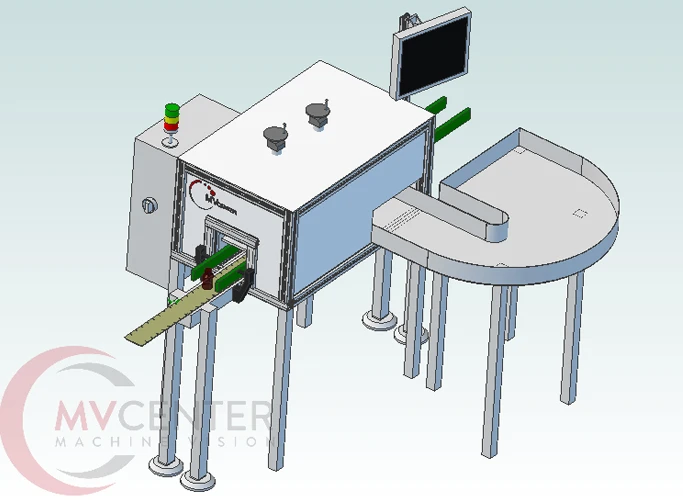

Damage control of glass bottles – 3D model of the bench