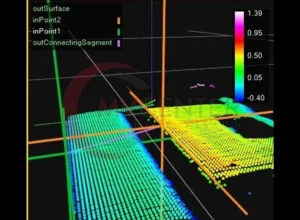

The quality control process in the pharmaceutical industry includes not only the inspection of the target product (e.g. tablets, capsules), but also the inspection of packaging. Manufacturing defects in packaging can directly affect the properties of the drug product, which is why careful quality control is so important. Over the past few years, we have implemented several vision inspection stations for white HDPE plastic bottles at a leading plastics manufacturer. The scope of the control:

- black spots (burnouts, inclusions) white spots (impurities, inclusions)

- the contour of the bottle (dents, deformations, etc.).

- discharges (including on the neck)

- bottle seal

- neck shape

The vision system is built into the production line, and has an automatic ejection process for defective parts.

The capacity of the system is 10 bottles per second, with a minimum defect size of 0.5 mm.

User panel – home screen.

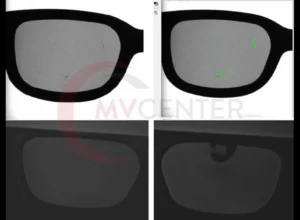

Detection of inclusions on a plastic bottle.

Detection of inclusions on a plastic bottle.

Detection of inclusions on a plastic bottle.

Detection of inclusions on a plastic bottle.