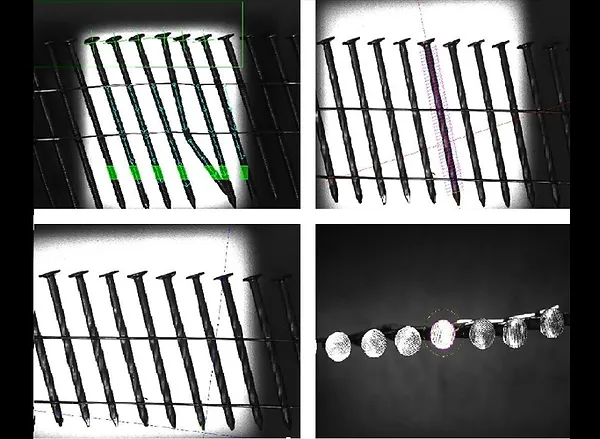

The nail inspection vision system was designed and built from the ground up for one of the largest nail factories in Poland. Nails connected by wire are inspected. The purpose of the inspection is to examine nails for:

- nail length – accuracy +/- 1mm

- nail inclination angle – accuracy +/- 1 degree

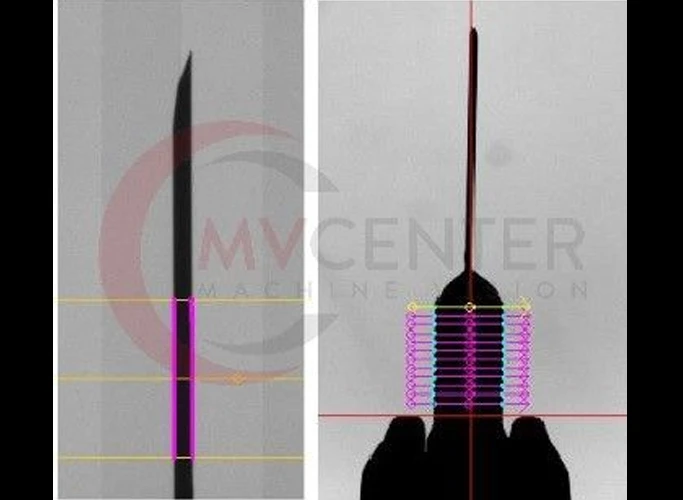

- curvature of the nail – accuracy +/- 0.5 mm

- nail diameter – accuracy +/- 0.2 mm

- spacing between nails attached to the wire

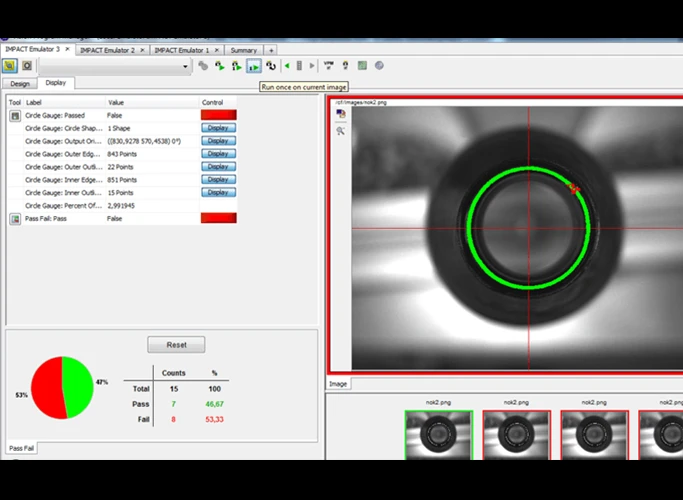

- nail exacerbations – information about the presence of OK/NOK

- head shape – accuracy +/- 0.2

The capacity of the production equipment is about 2,500 nails per minute.