Together with our partner S.C Solutions for one of the leaders in the automotive industry, we designed, delivered

and implemented a system for inspecting the threads and piston rods of shock absorbers. The device was integrated into the customer’s automated line and performs 100% inspection of all products in terms of:

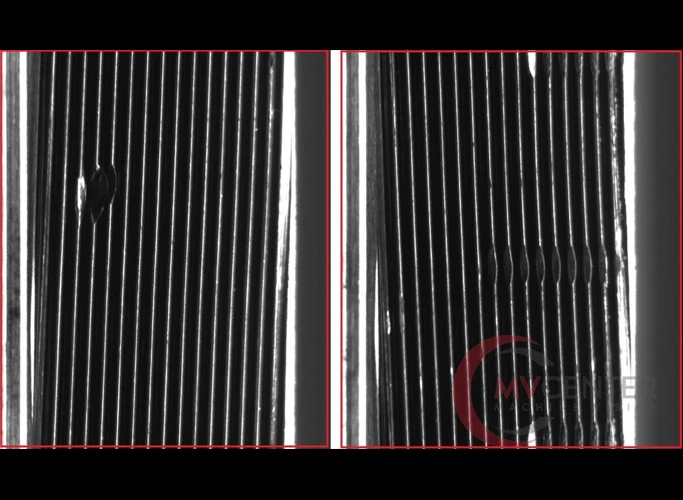

- Damage to the piston rod thread coils (whipped, torn, tarnished, broken),

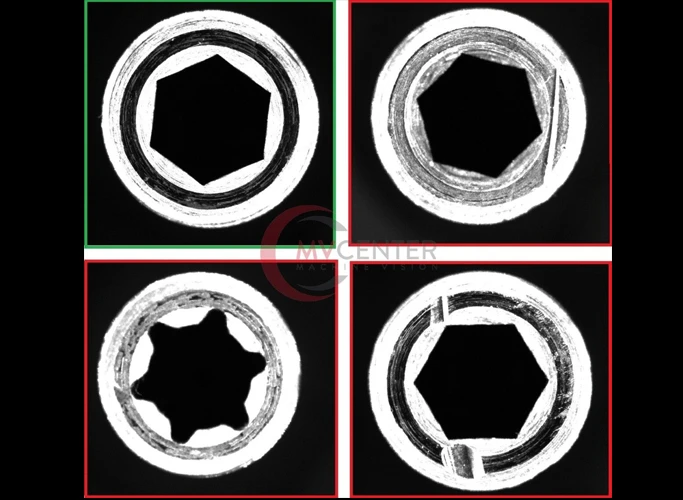

- Incorrectly made HEX/TORX holes in the piston rod face (no hole, double hole, improperly made hole),

The bench is equipped with a piston rod positioning system and a drive system that allows the position of the vision system head to be adjusted to the current reference. Inspection results are archived at the station and sent to the host system, which allows treaceability.

Shock absorber thread inspection station – built in an automatic production line.

Shock absorber thread inspection station – built in an automatic production line.

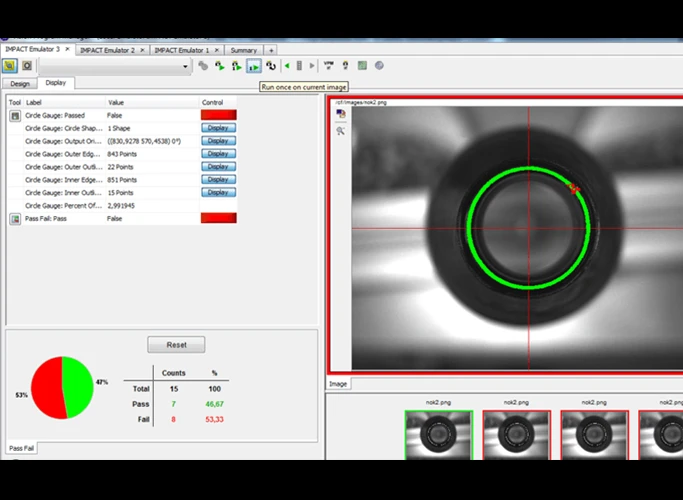

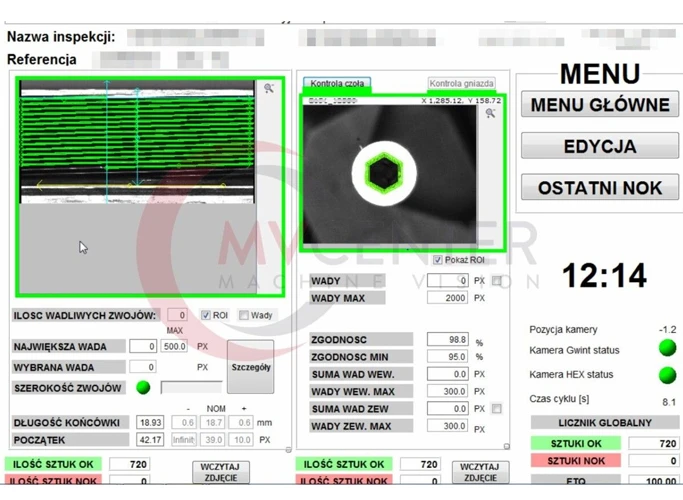

Thread control and hex – vision system user interface.

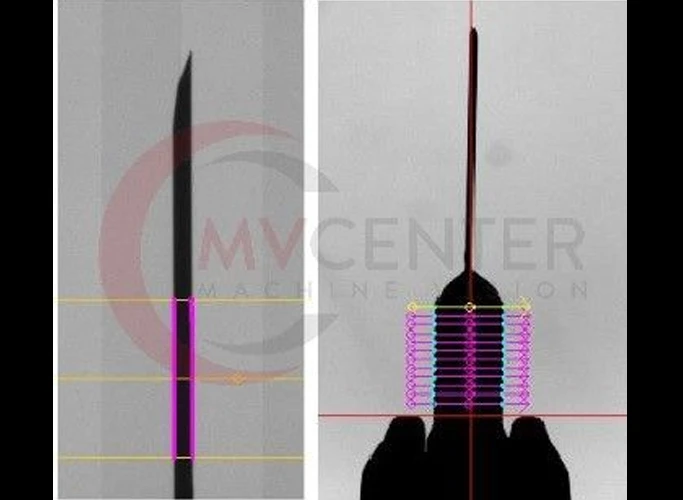

Hex/Torx – examples of piston rod tip damage detection.

Thread inspection — examples of damage detection.

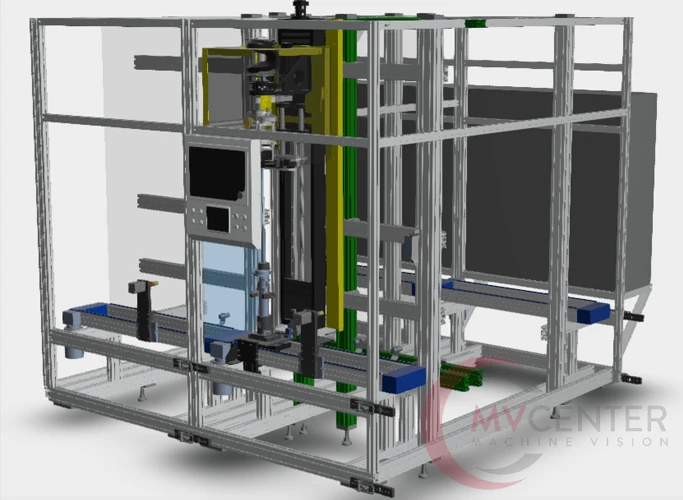

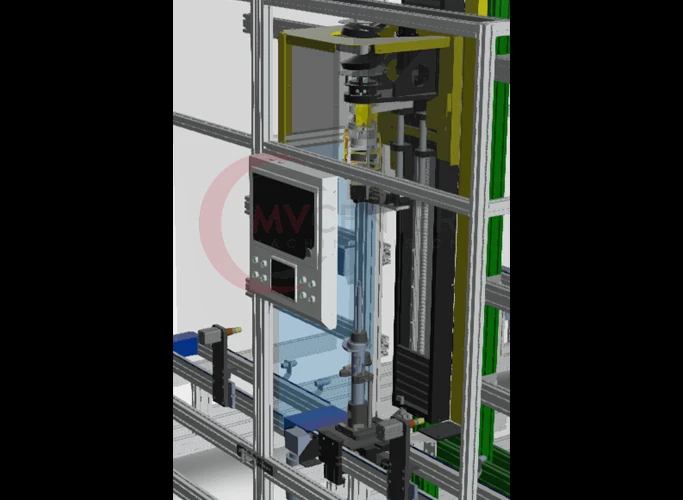

3D model of the thread inspection station.

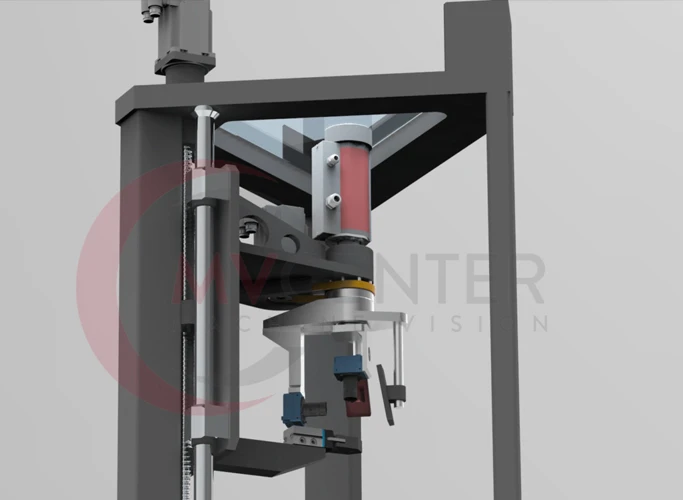

3D model of the vision system.