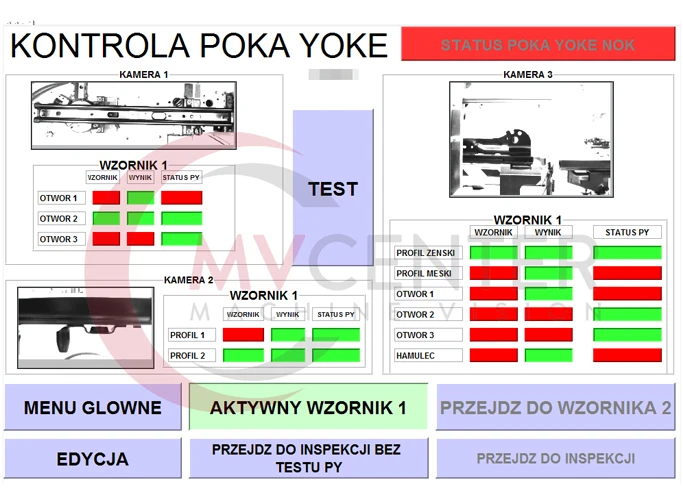

CONTROL AGAINST EVAPORATION OF CAR SEAT GUIDES. The task of the vision system at the profile pairing station is to verify that the operator has put the correct credentials (female and male profile) into the profile pairing machine. What to check?

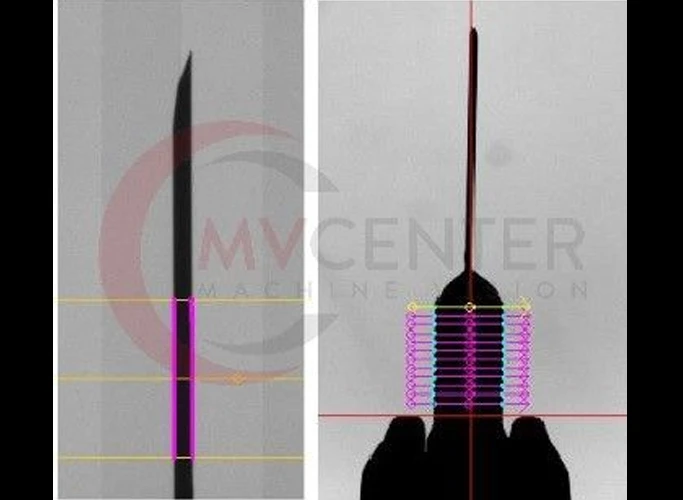

- the presence of elements such as pins, holes, pins,

- profile (left/right control),

- brake position (US and EU versions),

In the event of a negative inspection by the vision system, the pairing operation is interrupted and the defective attached piece is blocked

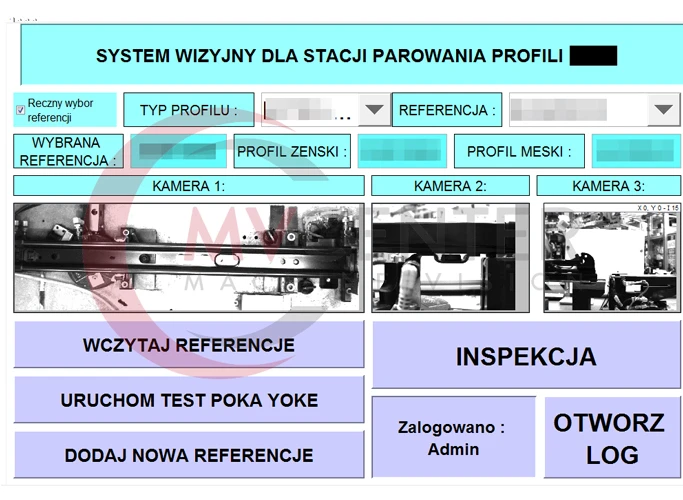

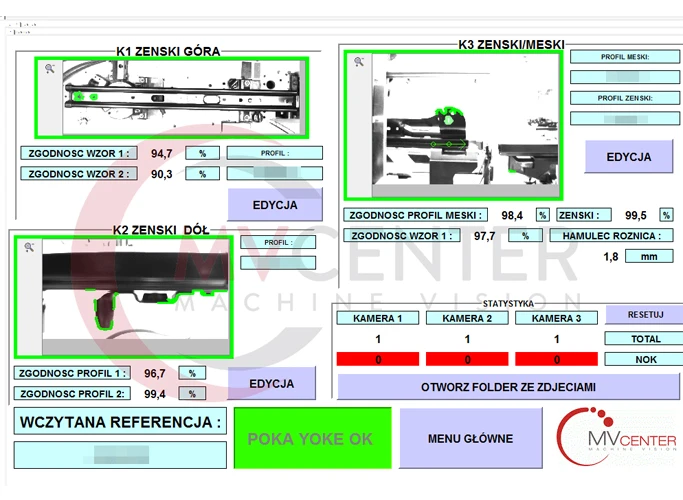

in the machine – until the operator releases it. The system software is equipped with a PokaYoke control module, which is responsible for checking the correctness of the workstation when changing to a new reference. The workstation is equipped with a touchscreen operator panel that displays, among other things:

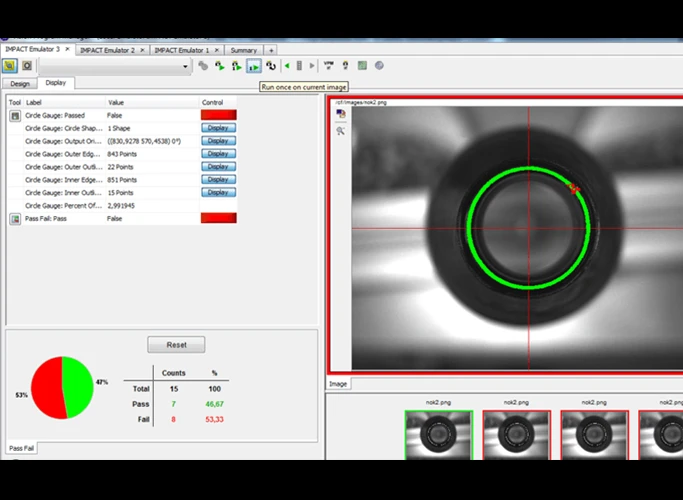

- preview of current inspection (current inspection photos)

- preview of inspection parameters (status of individual tools, compliance with the pattern in %. marking of relevant elements on the images in red/green depending on the inspection result)

- viewing statistics of the current inspection

- access to photos of defective components

- the ability to go to edit programs (after logging in to the appropriate access level)

Thanks to the Internet connection, the workstation was covered by remote technical support, which streamlined the implementation of the workstation in the critical production process.

Video system operator interface – home screen.

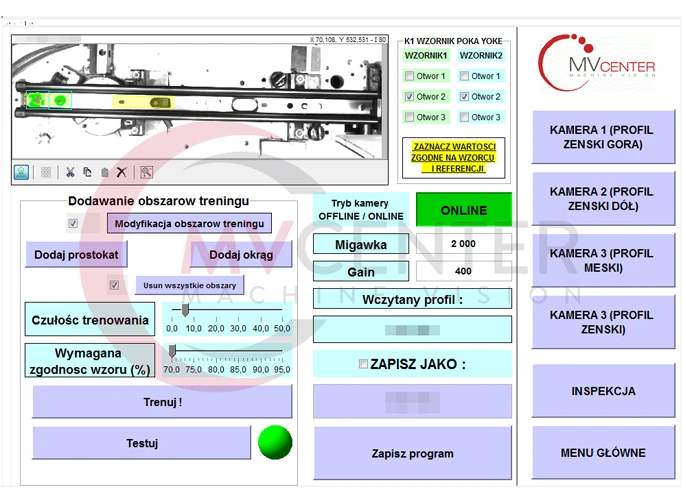

Video system operator interface – work screen.

Video system operator interface – edit.

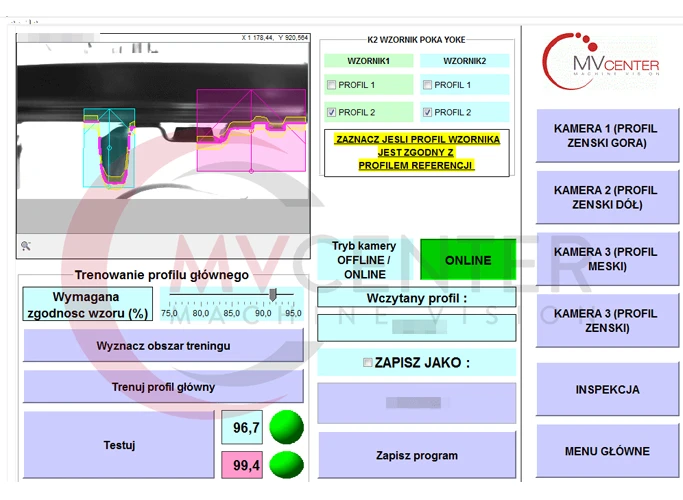

Video system operator interface – edit.

Video system operator interface – edit.

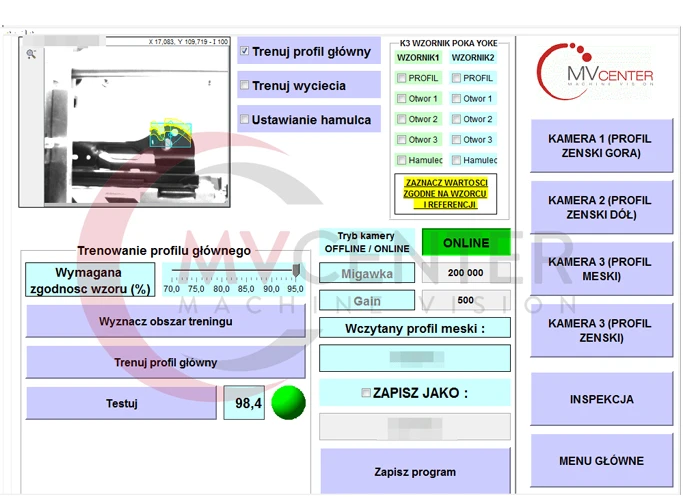

Video system operator interface – edit.

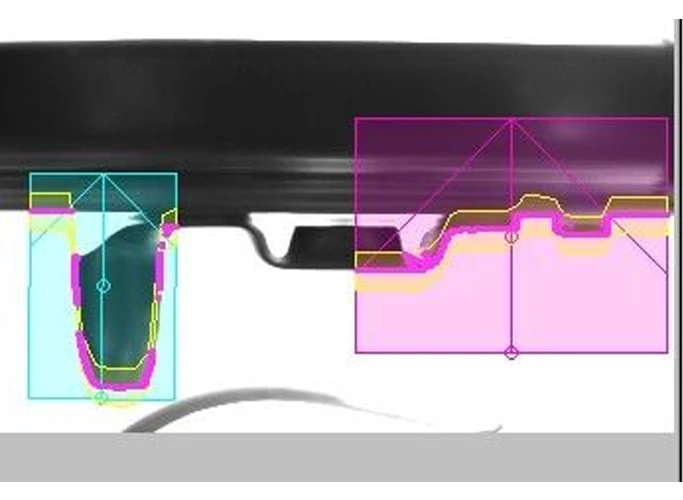

Contour detection of profile elements.