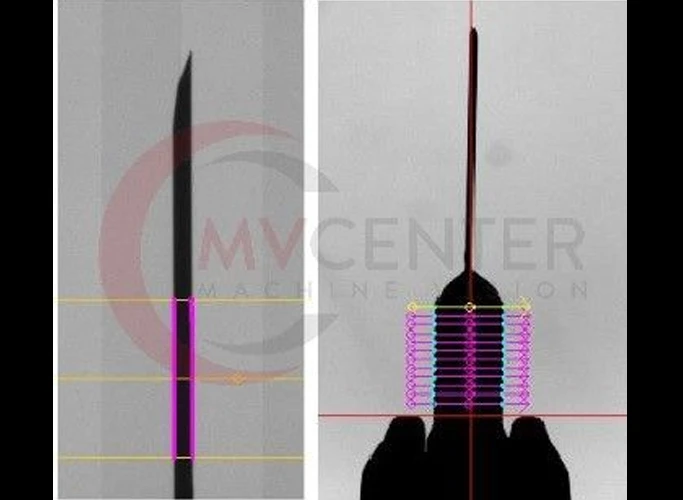

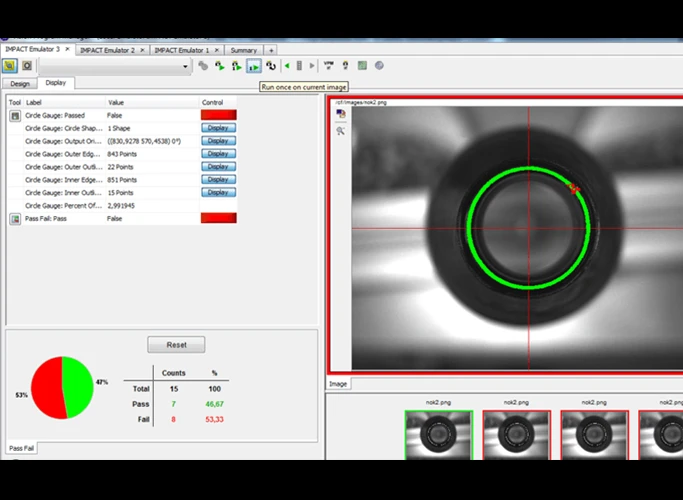

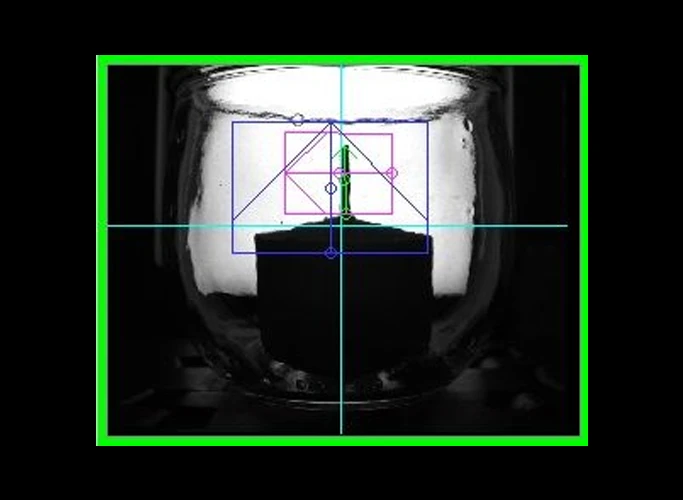

For a leading manufacturer of decorative candles, we made a comprehensive, multi-stage system for product inspection. Datalogic and Keyence components were used in the project. Decorative products are subject to detailed inspection for aesthetic qualities – among other things. correct printing, the central position of the wick (accuracy of up to 1 mm and 5 degrees of deviation), proper flooding (up to 1 mm in height) or mechanical damage.

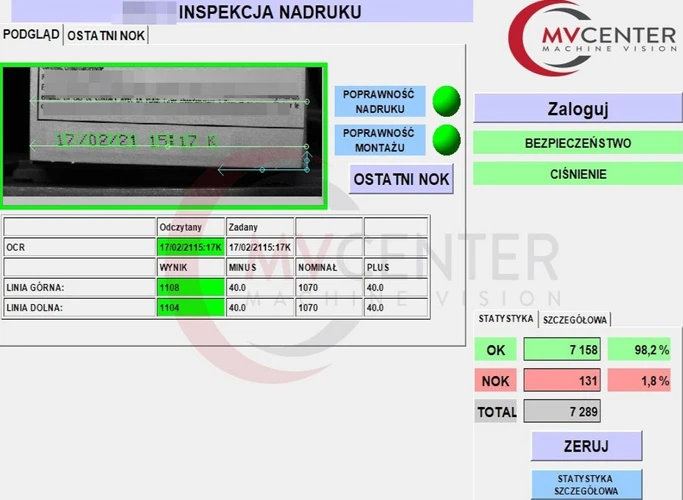

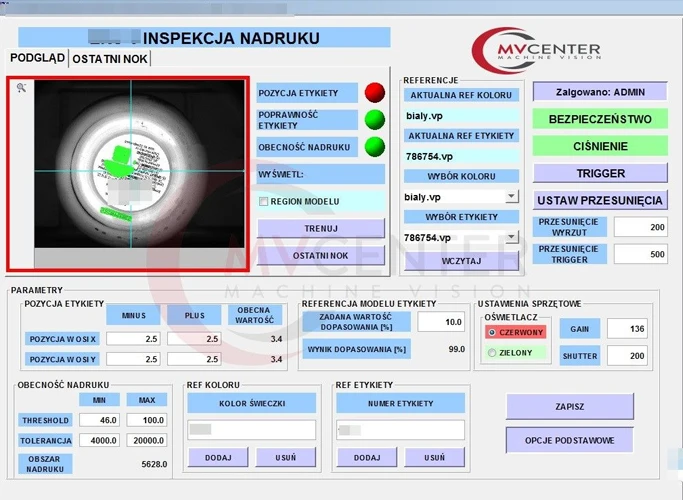

In addition, such features as the correctness of the label – both its position and correct data or the correctness of the bar code – are subject to inspection. The system is equipped with a functional operator panel. It enables:

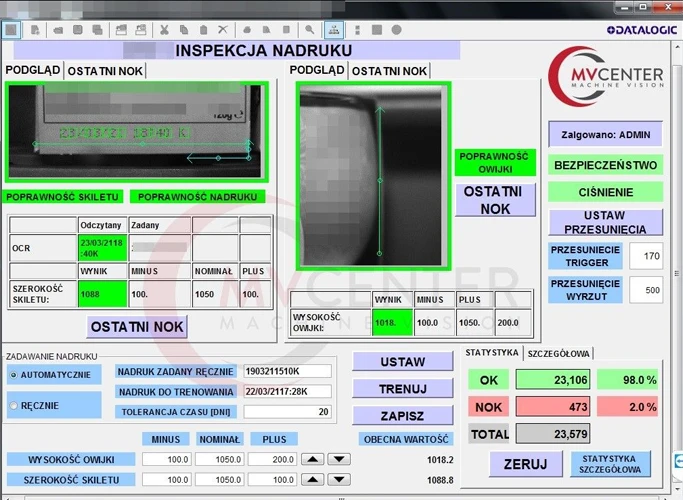

- Display of inspection results with photos,

- Display overall and detailed statistics on rejected pieces,

- Display images of the last rejected pieces,

- Making changes to video inspection settings.

If the system detects a defect, the candle is removed from the line using a pneumatic ejector.

Vision system for candle inspection – wick and molding detection.

Vision system for candle inspection – label detection and inkjet printing.

A vision system for inspecting candles – reading the imprint of the production date and inspecting the closure of the wrapper.

Inkjet print reading – production date