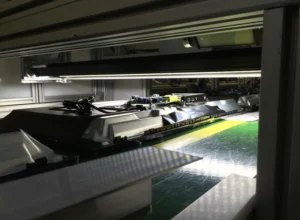

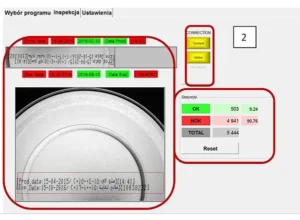

For a factory producing candles of various types, a system for vision inspection of “heaters” was designed and manufactured.

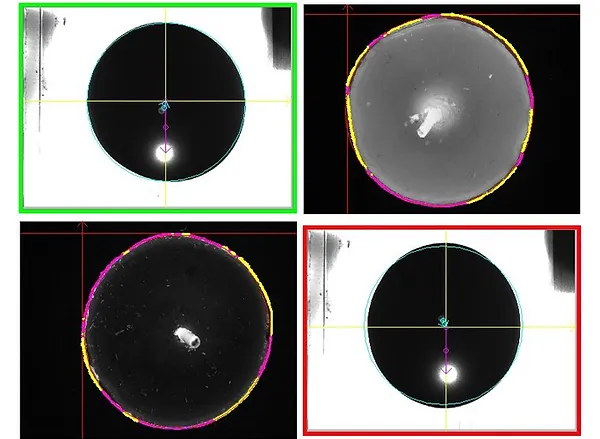

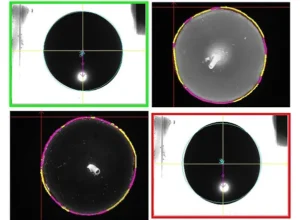

The control is subject to:

- heater shape

- crease detection

- checking the ovality of the cup

Minimum detectable crease with a continuous length of 2 mm at the perimeter. – paraffin flooding level (spot) – measurement accuracy of 0.25 mm. – The presence and centricity of the wick with an accuracy of 1 mm.