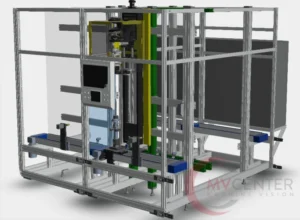

The project involved the creation of a semi-automated robotic inspection station for aluminum castings. The project used an ABB robot along with a KEYENCE XG-2200 vision system and specialized OPTO-ENGINEERING optics.

The task of inspection is to indicate:

- presence of an insert in the casting

- knocking out the insert mounting element

- skipping the last reel of the insert during knockout

- presence of rivets

- color/size of rivets installed

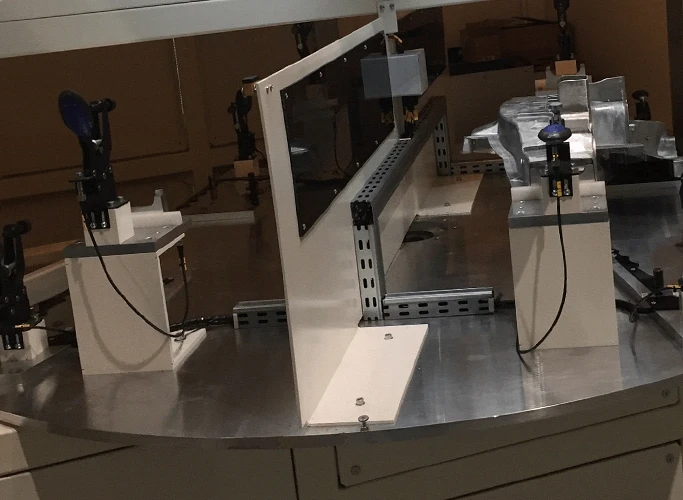

The workpiece is placed in one of two slots, by the operator, while inspection is done by a camera on the robot’s arm. The inspection time for the entire component is approx. 30 sec. A major challenge of the project was the numerous hole contaminants in the form of aluminum chips and hairs. However, thanks to the solutions used, the inspection is flawless.

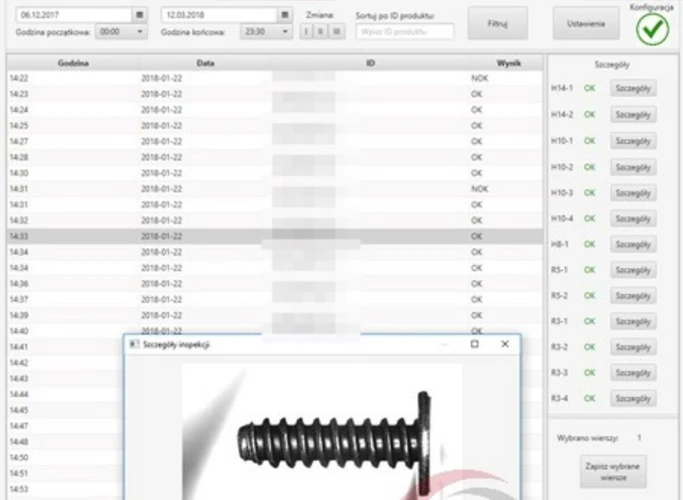

An interesting element of the program is the data viewing application – the operator has the ability to view images from a given shift (OK details only or NOK only) search by inspection date or part ID. The program allows you to view photos of each piece from each inspection. In addition, the system is equipped with the Master Parts – Poka Yoke function, which makes it possible to verify the system 2x per shift.

Rotary table of the vision inspection station.

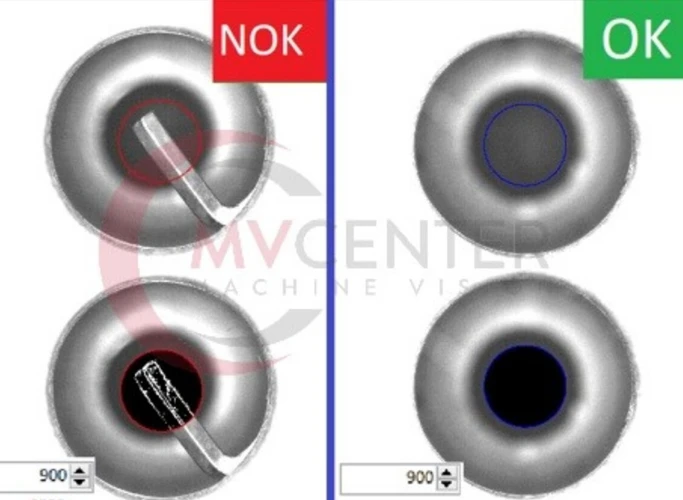

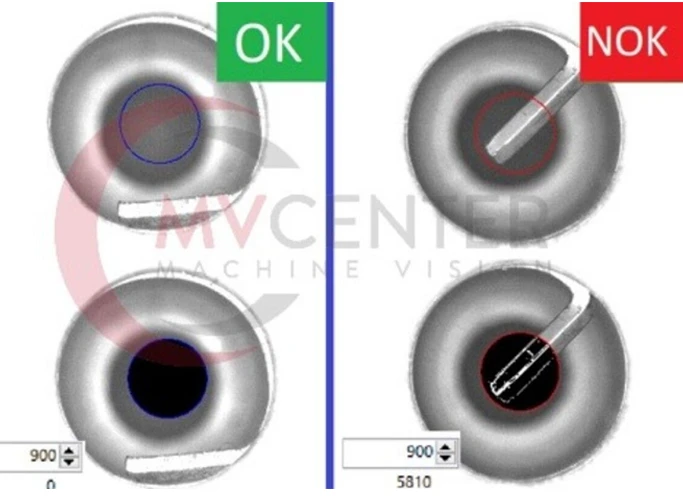

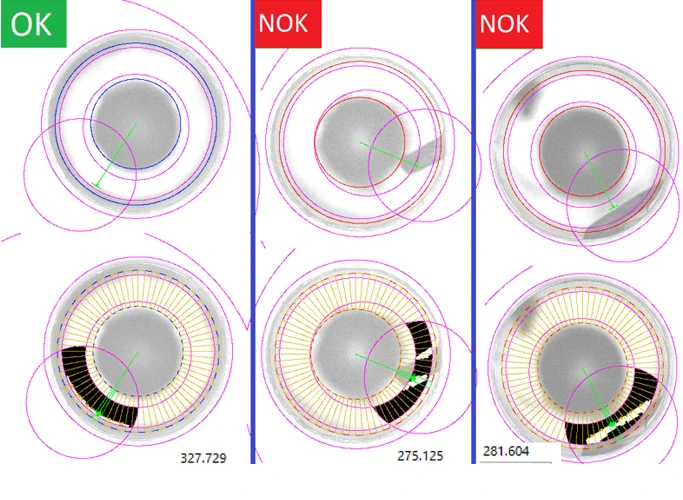

Inspection of the threaded insert – knocked out tip, pulled thread coil.

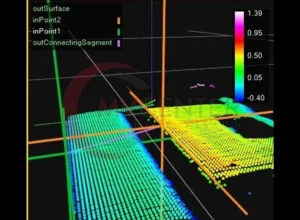

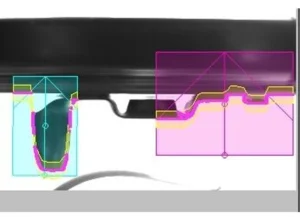

Image analysis and algorithm for inspecting the threaded insert – tip knockout, pulled thread coil.

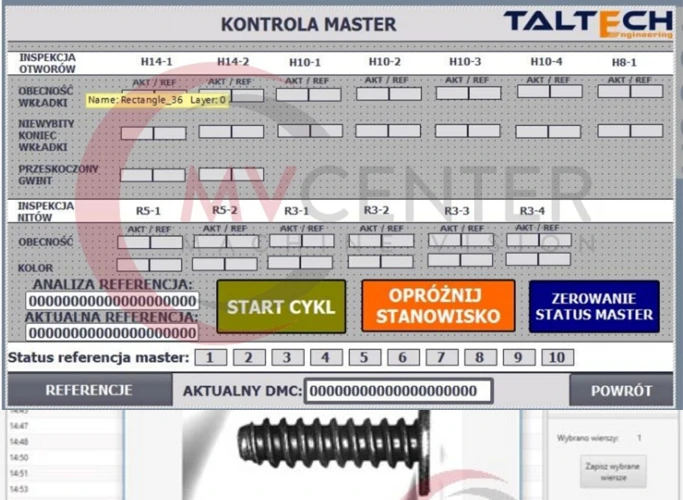

Poka Yoke (Master Parts) control screen – autochallenge of system correctness

An application for viewing inspection data and analyzing inspection reports.

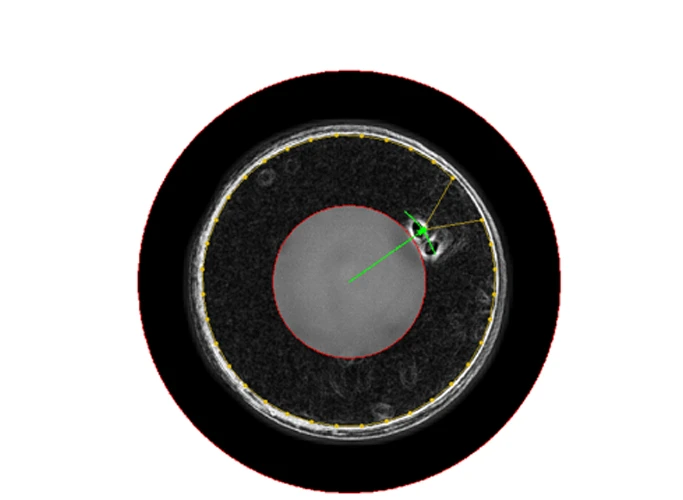

Detected defect in the threaded insert.

Examples of NOK detection.