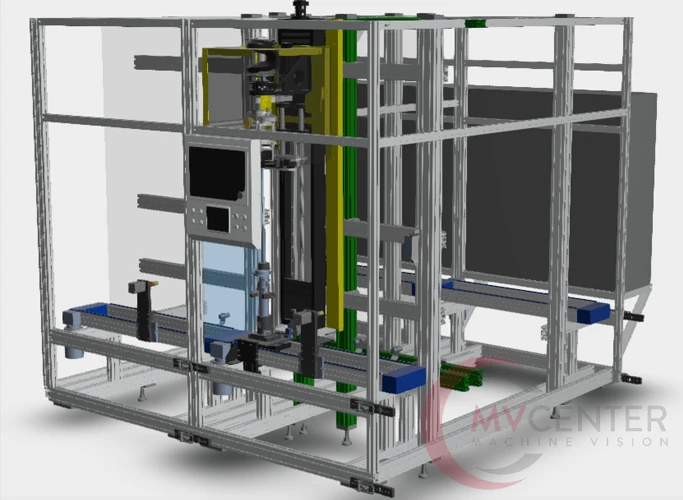

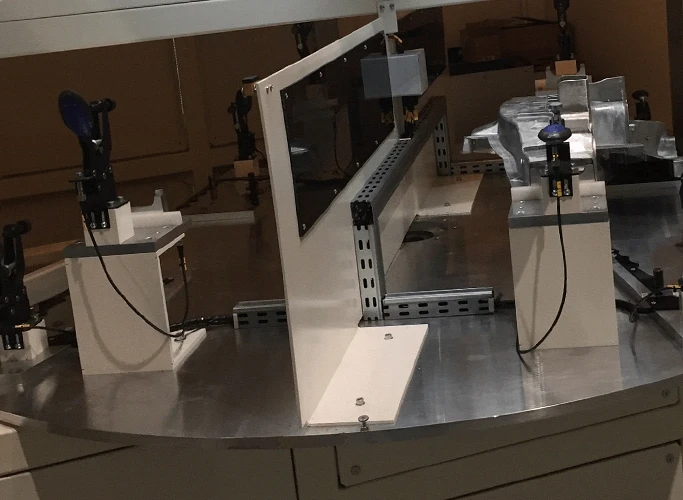

3D inspection of plastic component with gasket

We present to you one of the applications made by the MV Center Vision Systems Company using 3D technology. The described project consisted of hardware selection, inspection software and integration of the vision system into the production line. Aim of the project Quality control of the installation of the gasket on the plastic component (car […]

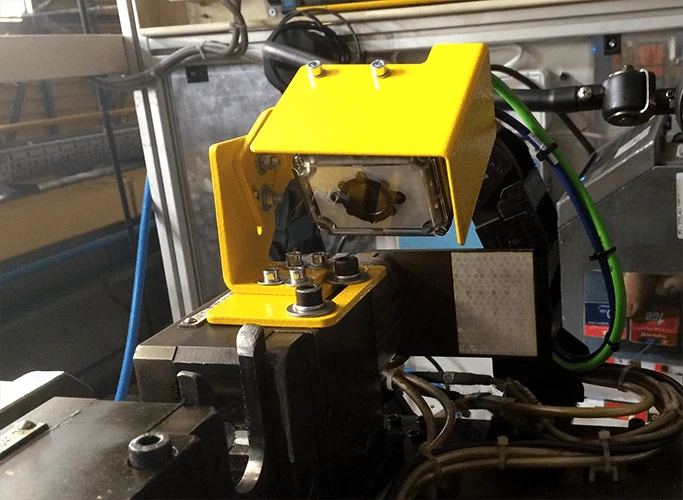

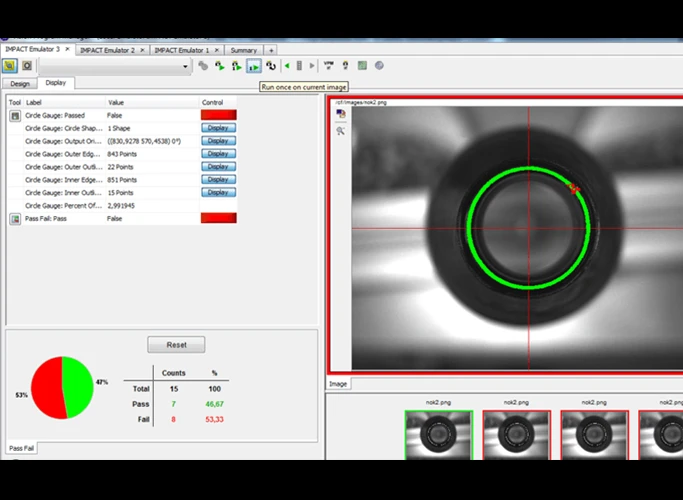

Vision inspection of the piston rod and thread of an automotive shock absorber.

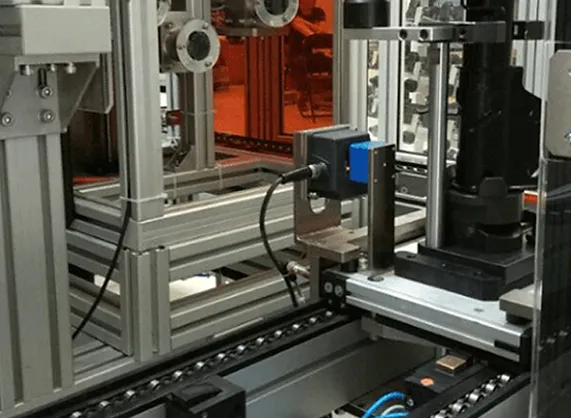

Together with our partner S.C Solutions for one of the leaders in the automotive industry, we designed, deliveredand implemented a system for inspecting the threads and piston rods of shock absorbers. The device was integrated into the customer’s automated line and performs 100% inspection of all products in terms of: The bench is equipped with […]

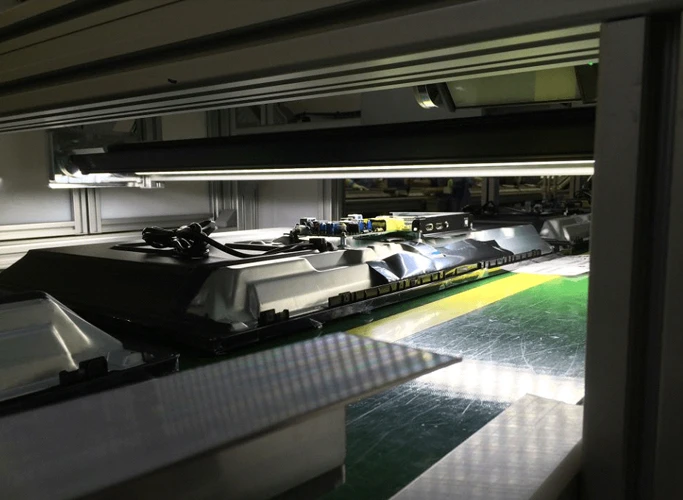

Vision inspection of vehicle reflectors.

A vision system for inspecting the presence of embossed prints on car reflectors is a very interesting example of how knowledge of optics, lighting and optical filters can be used to create an application that at first glance seems impossible. The task of the system we constructed is to detect the approval printing on car […]

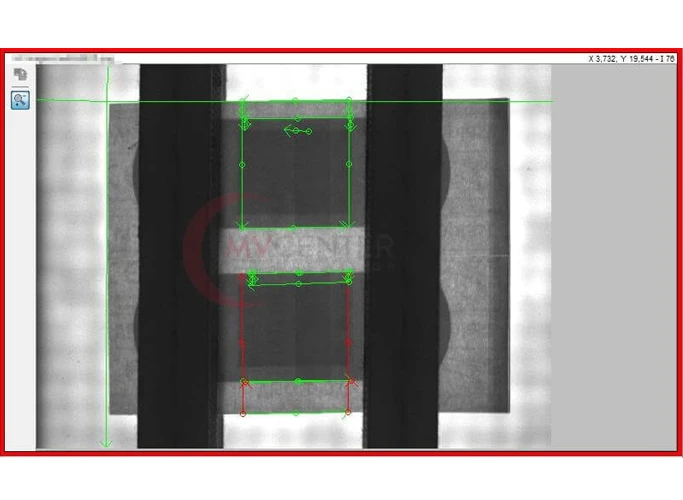

Vision inspection of vehicle seat profiles.

CONTROL AGAINST EVAPORATION OF CAR SEAT GUIDES. The task of the vision system at the profile pairing station is to verify that the operator has put the correct credentials (female and male profile) into the profile pairing machine. What to check? In the event of a negative inspection by the vision system, the pairing operation […]

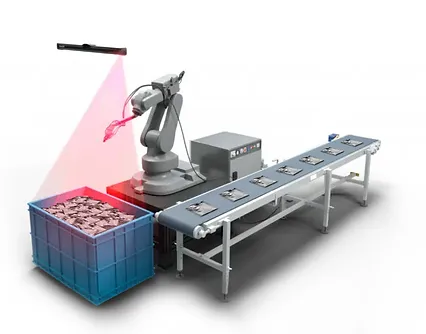

Vision inspection and sorting of rubber parts.

For one of the largest rubber processing factories in Poland, a complex station was made for sorting 16 different products consisting of rubber, plastic and steel/aluminum components. The equipment is designed to sort through all the pieces and separate them according to set parameters, as well as inspect them for type and the presence of […]

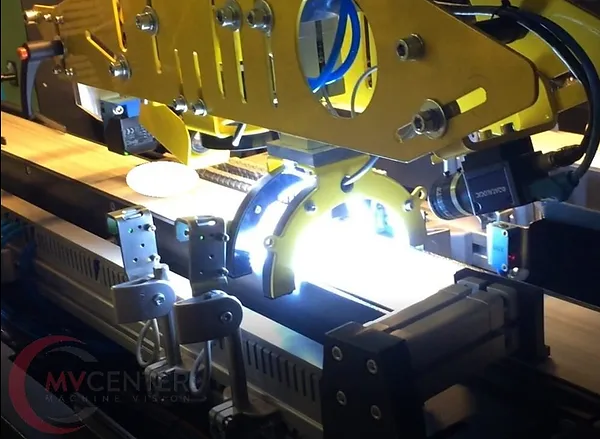

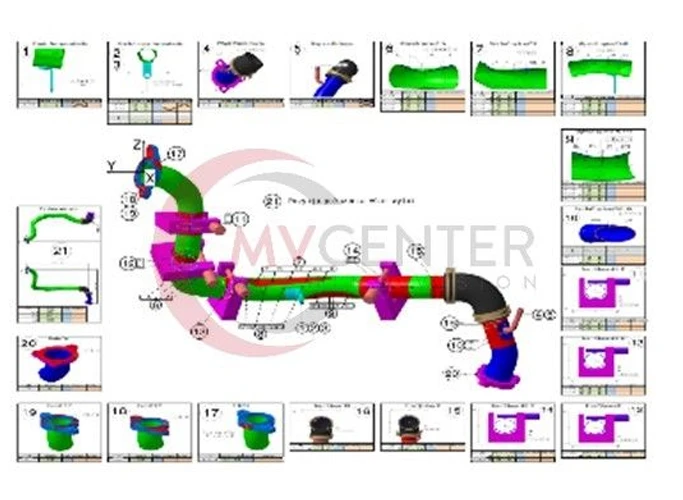

Checking the geometry of the EGR pipe in 3D space.

MV Center Vision Systems engineers have developed a semi-automatic EGR pipe geometry measurement station. The workstation was equipped with a rotary table including a mounting socket and a cage for a precision (+/- 0.02 mm positioning accuracy) MITSUBISHI RV-7FLM robot. An execution unit for the measurement – a GOCATOR 2340 3D scanner – was installed […]

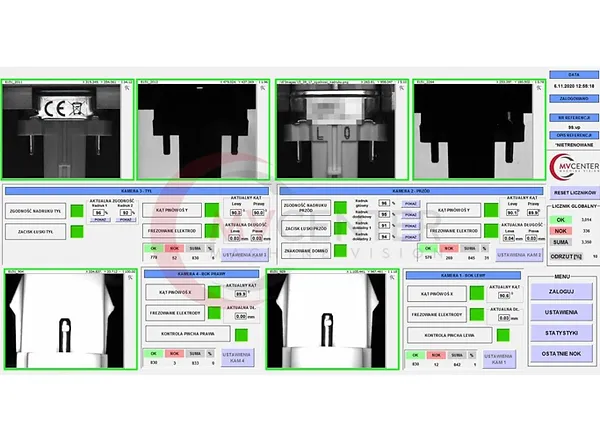

Vision inspection of shock absorbers

A system for vision inspection of a shock absorber was constructed for one of the largest manufacturers in the automotive industry. The inspection is aimed at: The entire shock absorber is controlled by 4 independently operating cameras integrated with a vision processor. Vision inspection of shock absorbers

Vision inspection of aluminum castings.

The project involved the creation of a semi-automated robotic inspection station for aluminum castings. The project used an ABB robot along with a KEYENCE XG-2200 vision system and specialized OPTO-ENGINEERING optics. The task of inspection is to indicate: The workpiece is placed in one of two slots, by the operator, while inspection is done by […]

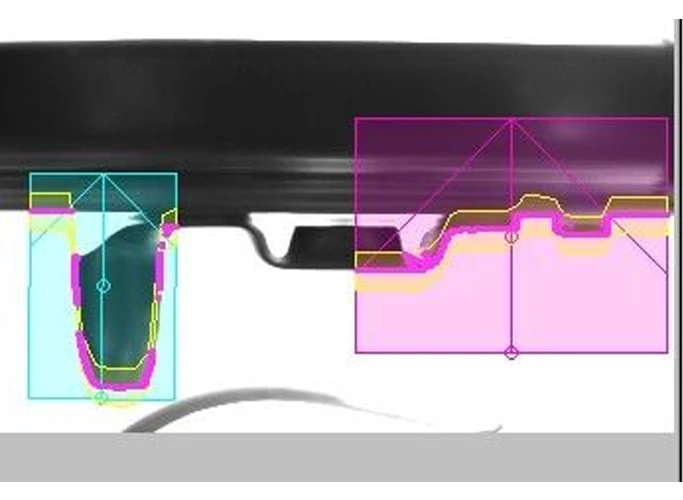

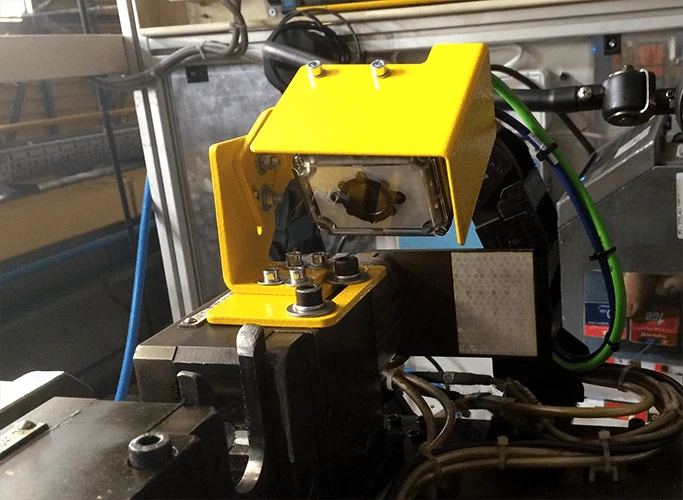

Vision inspection of the seal on the half-axle.

In April 2018, a project involving the implementation of two vision inspection stations for a rubber gasket was implemented. The gasket is located on a component that is part of a car’s suspension. The vision system detects the presence or absence of a seal, depending on the reference (manufactured type). If a discrepancy is detected, […]

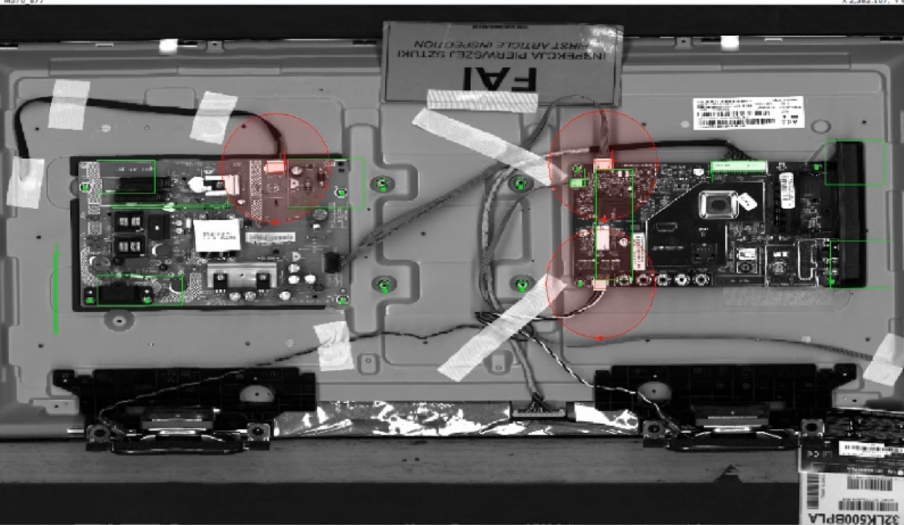

How TPV maintains 100% error-free production of TV sets for Philips already on nine lines in Gorzow.

What is the TPV company? TPV Displays Poland is a manufacturer of LCD and OLED TVs and SSBs. It specializes in manufacturing activities in the form of ODM and OEM, and develops its own brands. It has ten assembly lines for televisions and three lines producing printed circuit boards. The Gorzow factory is a leader […]

History of Machine Vision

Mr. Ford would be proud of us. Widely regarded as the father of industrial mass production, Henry Ford had a habit of personally inspecting every automobile that rolled off the belts of his factory. He signed it with his own signature, which illustrates well his almost obsessive attention to the quality of the legendary Model […]

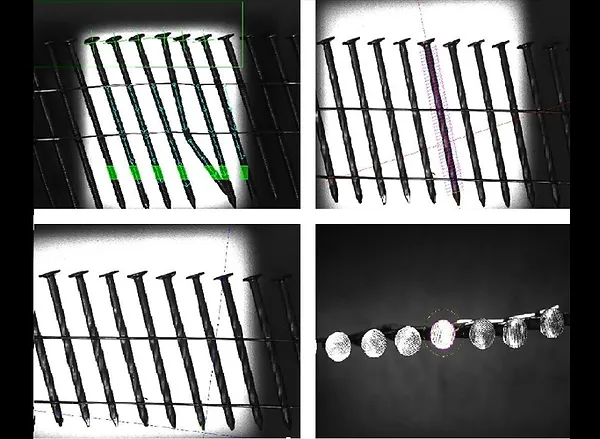

Vision inspection of nails.

The nail inspection vision system was designed and built from the ground up for one of the largest nail factories in Poland. Nails connected by wire are inspected. The purpose of the inspection is to examine nails for: The capacity of the production equipment is about 2,500 nails per minute.

Inspection of Teflon tape defects.

The task of the system is to inspect the surface of the Teflon strip before cutting to detect defects in the form of inclusions, holes, cracks and PTFE deficiencies. Detection of the above-mentioned defects results in marking the location of the defect with a marking head. The tape marking system consists of two units: A […]

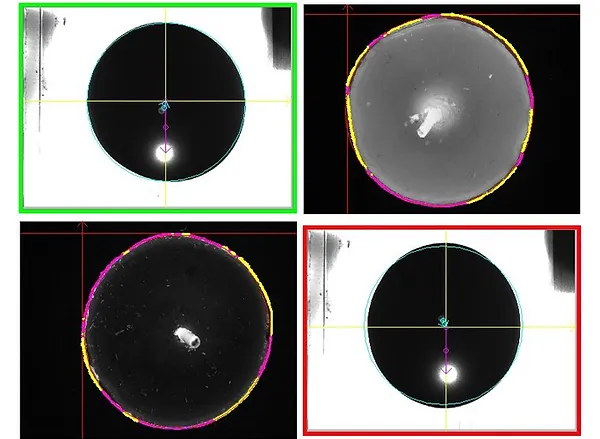

Tealight vision inspection.

For a factory producing candles of various types, a system for vision inspection of “heaters” was designed and manufactured. The control is subject to: Minimum detectable crease with a continuous length of 2 mm at the perimeter. – paraffin flooding level (spot) – measurement accuracy of 0.25 mm. – The presence and centricity of the […]

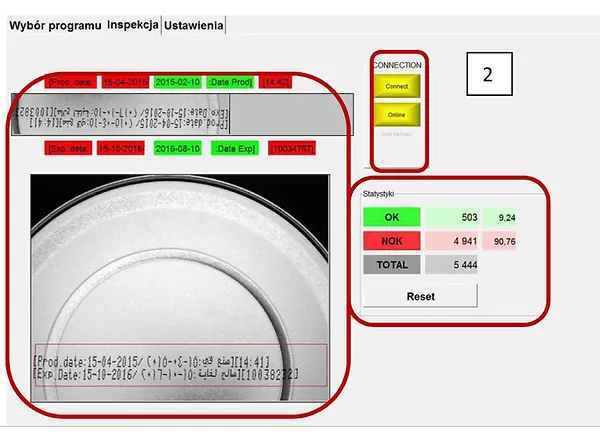

OCR control.

The system checks the quality and accuracy of Arabic printing ( including expiration and production dates) on metal cans. The system checks its presence and completeness as well as its correctness – it reads the subsequent marks and informs about an illegible or incorrect mark. Pieces that do not meet inspection requirements are automatically removed […]

Vision inspection of decorative candles.

For a leading manufacturer of decorative candles, we made a comprehensive, multi-stage system for product inspection. Datalogic and Keyence components were used in the project. Decorative products are subject to detailed inspection for aesthetic qualities – among other things. correct printing, the central position of the wick (accuracy of up to 1 mm and 5 […]

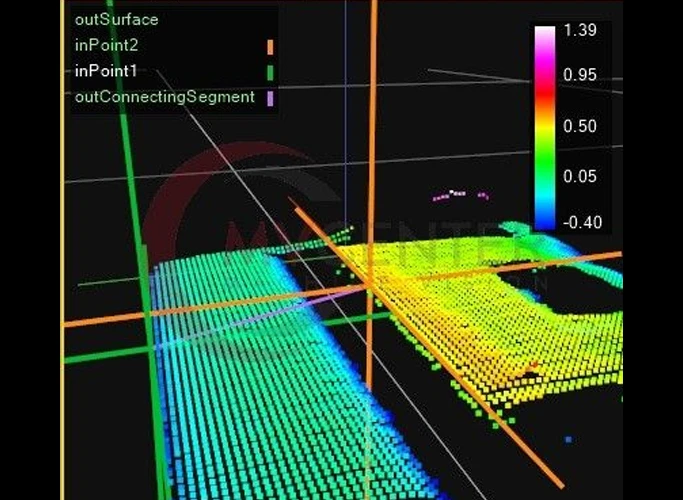

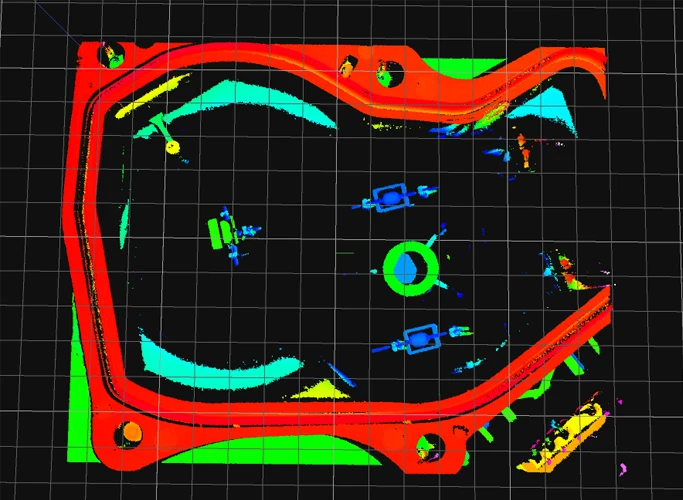

3D automotive parts inspection.

Inspection of 3D automotive parts is another inspection of the many fine and shiny parts inside the cover casing of a control component used in the automotive industry. The inspection takes place using 3D technology. The inspection included such items as: A 3D scanner using a laser line was used to retrieve the point cloud. […]

Bulb vision inspection.

The project was carried out for one of the largest bulb and lamp manufacturers in Poland. The task of the system is to control the correctness of the product and the correctness of the printing on the bulb element. The system consists of a single station equipped with four cameras and eight illuminators. Each camera […]

TV Components.

The entire project includes the supply of 9 complete stations for vision inspection of TV components. The client is one of the largest manufacturers in Poland. After ordering the first pilot station in 2016, testing it and optimizing it, the customer decided to order 8 more stations, automating vision inspection on all 9 production lines […]

Control of lids for hot and cold beverages.

We present you with a description of the inspection of a vision system for hot and cold beverage lids. The application’s task is to detect and eliminate contaminated or dirty lids. The use of biomass is associated with a much larger number of inclusions of very different colors and shapes. The project described here consisted […]

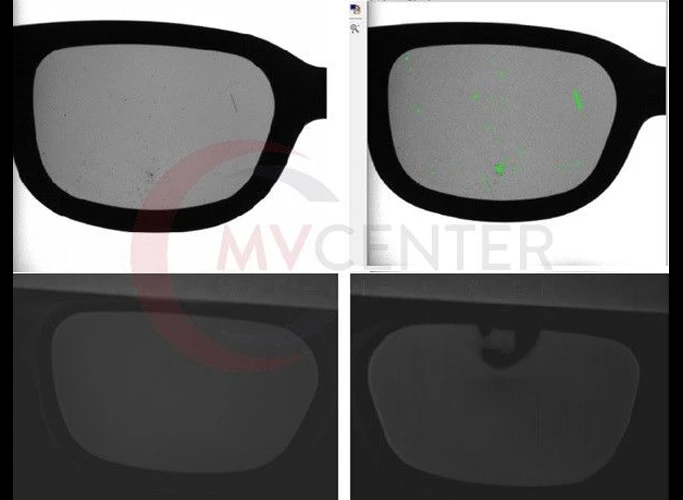

Vision control of 3D glasses.

For one customer, 3 vision control stations for 3D glasses used in movie theaters were created. Each station is equipped with 7 Datalogic cameras that are designed to: The whole thing has been encapsulated in one compact and built-in workstation integrated with the customer’s conveyor belt. Inspection results are transmitted to the master control system […]

Automatic inspection of PET bottles.

A project involving two PET bottle inspection stations has been implemented at a leading beverage manufacturer. Station one inspects the presence, position and correctness of the tightening of the cap, as well as the presence and quality of the retaining ring. This position also controls the level of brine in the bottle. At the second […]

Video inspection system of the household appliance panel

Application name: Inspection of printing and inclusions on household appliance panels. Scope of control: Developing a panel print inspection application for the pad-printed home appliance industry is a challenge due to the huge number of different references and the small size of typical defects (inclusions, underprinting) – detection of defects with a size >=0.1 mm […]

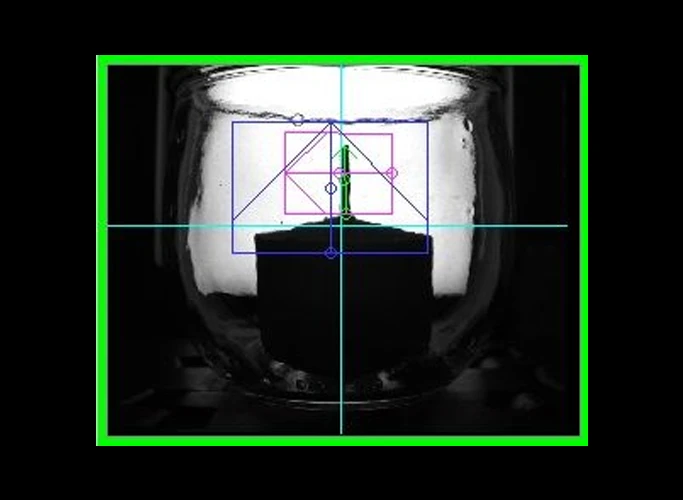

Control of a pharmaceutical bottle with a dropper.

For our client, a manufacturer in the pharmaceutical industry, we built a vision system to inspect the bottle with a therapeutic preparation. the inspections were subject to: Glass bottle inspection. Control of the level of filling and reading the date of production / LOT. Closure control. Closure control. Inspection of the presence of the dispenser.

Vision inspection of dressing patches.

For our client, a manufacturer of dressing materials, we built a vision system to control the position of the nonwoven material on the patch. The challenge we faced was inspecting 30 slices in one second! The patches subject to inspection were flesh-colored, transparent and had prints. The slices inspected were flesh-colored, transparent, and with different […]

Plastic bottle inspection.

The quality control process in the pharmaceutical industry includes not only the inspection of the target product (e.g. tablets, capsules), but also the inspection of packaging. Manufacturing defects in packaging can directly affect the properties of the drug product, which is why careful quality control is so important. Over the past few years, we have […]

Vision inspection of glass bottles.

A vision inspection station for glass bottles was made for one pharmaceutical company. Inspection involves inspecting the top surface of the bottle neck, where cavities/chips or distortions often occur, preventing the final product from being properly sealed. The multi-camera vision system successfully detects and uses a pneumatic ejection system to eliminate defective pieces from the […]

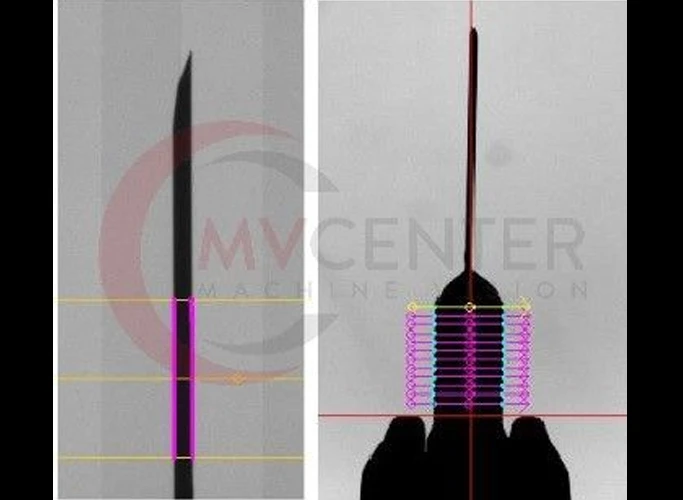

A vision system for inspecting safe punctures.

The system’s task is to control the correctness of the safety puncture used in insulin delivery devices, At the various stages of production. The system consists of 3 workstations that inspect 20 workpieces on a pallet simultaneously. The stations are set according to the position on the machine: The system is equipped with an operator […]

Presentation from Automotive CEE Day

What is machine vision?

Control you can trust. In a free market, the key to a brand’s long-term success is the high quality of its products. The problem of its effective control becomes particularly acute when “manual” methods of control no longer work. Industrial production methods produce a lot, quickly and with reproducible quality, so they need equally […]